Recap:

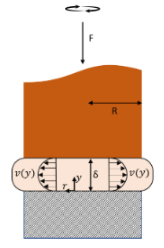

Previously the lab procedure and motivations behind this project were discussed. The experiment involves a polymer rod that spins to induce viscous heating shown in Figure 1. Using viscous heating, 3D printing could potentially be more energy efficient and allow print speeds faster than current printers.

Figure 1: Simplified experimental setup[1]

Testing:

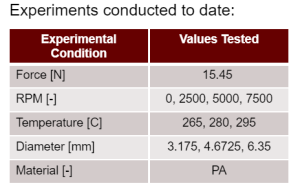

Figure 2: Experimental parameters[2]

Currently testing for 3 separate RPMs, temperatures, and diameters have been completed and analyzed. There has also been new testing at several different forces, but the data is yet to be analyzed. Introducing higher force values around 40 [N] has caused buckling to occur in several tests. This buckling problem is a limiting factor of print speeds in current FFF printers today. This issue has caused a redesign of the testing setup. The new setup that is currently being explored is a plate with drilled holes to reduce weight. This new plate will allow for data collection at lower force values.

Future testing will include the lower force values achieved from a lighter plate as well as increasing the RPM upwards towards 20,000. This RPM testing however will likely be done once the prototype printer is complete and is out of the scope of this project.

Experimental Procedure:

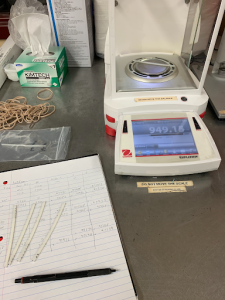

This testing is preliminary, and as such a simple setup is used to conduct the experiments while a prototype is being built. To perform a test, first 10 cm long PA samples are cut and weighed as shown in Figure 3.

Figure 3: Weighing the test samples

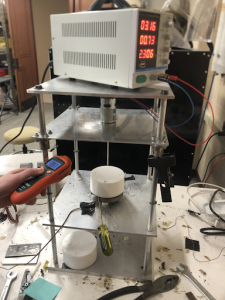

Next, the router motor must be calibrated to the correct speed. This is done by altering the voltage of the motor, while the RPM’s are measured using a tachometer as pictured below in Figure 3.

Figure 4: Measuring Router Moor RPM’s

After the speed of the motor has been set, the heated bed can be set to the desired temperature and the guide block is set in place. The sample is then attached to the router motor and lowered into the guide block. The motor is turned on and the sample is lowered until it reaches the heated bed, this begins the test. The test duration is 1 min, during which the RPM’s are monitored to ensure that they are within an acceptable range of the desired value as shown in Figure 5 below.

Figure 5: Monitoring RPM’s during testing

After 1 minute the sample is removed from the test apparatus and is weighed to determine the amount of material that was melted throughout the experiment. The heated bed is then cleaned of any melted material before beginning the next test.

Preliminary Findings:

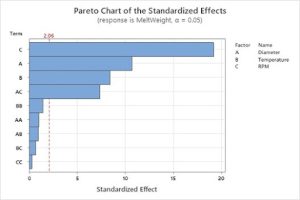

There have been several important findings from the first analysis of experimental data. Figure 6 is a Pareto chart that shows the significance of the different variables being tested. This shows that of the three main parameters being tested in our experiments, the RPM’s have the greatest effect on overall material melt.

Figure 6: Pareto Chart of experimental parameters[2]

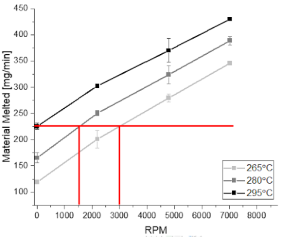

This result is promising as it will allow for the desired melt rate of an experiment to be reached more efficiently through the combination of viscous heating and the traditional heating elements. This relationship is shown in Figure 7 below.

Figure 7: Correlations between temperature and RPM’s[2]

Following the horizontal red line in Figure 7, it can be seen that the melting rate of 225 mg/min achieved by a test at 295 C and 0 RPM can be equivalently reached at a temperature of 265 C with 3000 RPM. In the future, the addition of viscous heating to 3D printers should allow for much greater melting speeds, leading to shorter print times.

References:

[1] J. Quintana, “Understanding Melting in Fused Filament Fabrication Process” Ph.D. dissertation, Dept. Mechanical Eng. , Univ., Madison., WI, US, 2021. Available: Understanding Melting in Fused Filament Fabrication Process

[2] T. Osswald, A. Roman, ‘Accelerating FFF Printing via Viscous Heating – Experimental Findings and Predictive Algorithms’, University of Wisconsin-Madison, 2022. Accelerating FFF Printing via Viscous Heating – Experimental Findings and Predictive Algorithms