Harkirat Singh Ubhi and Vigneshwar Nagaraj

Mechanical Engineering, University of Wisconsin-Madison

Abstract

This project explores the design and fabrication of a detachable splash protector for sports shoes using dual-material 3D printing. The goal is to prevent water ingress during activities in wet environments without compromising comfort or usability. The design features a rigid front section made from polylactic acid (PLA) to block water splashes and a flexible top made from thermoplastic polyurethane (TPU) to ensure a snug, comfortable fit around the ankle.

CAD modeling was performed based on 3D-scanned shoe geometry, and the protector was fabricated using separate prints for PLA and TPU due to printer constraints. Through multiple design iterations, improvements were made to the fit and printability of the component. The final prototype was evaluated based on its ease of use, water protection capability, and material performance.

This study demonstrates the effectiveness of dual-material additive manufacturing in creating hybrid, user-friendly protective gear for wearable applications. The results support the potential of multi-material 3D printing for developing customizable, functional accessories in consumer sportswear.

Introduction

Water splashing into sports shoes while walking or running in wet conditions presents both discomfort and performance issues for athletes and recreational users alike. This problem is especially prominent in environments such as rain-soaked tracks, muddy trails, or urban pavements where puddles are common. Most sports shoes are designed with breathable mesh uppers to improve ventilation and reduce weight; however, this same design allows water to easily penetrate, resulting in wet socks, skin irritation, and decreased athletic performance.

Despite the widespread nature of this issue, conventional footwear designs do not provide targeted, detachable, or customizable protection specifically aimed at preventing water ingress during such activities. Commercial solutions, such as waterproof shoes or covers, tend to compromise comfort, breathability, or cost-effectiveness. These products often lack adaptability for varying foot shapes or shoe types and are rarely aesthetically integrated into the shoe itself.

To address this practical challenge, our project proposes the development of an easily attachable and detachable splash protector specifically engineered for sports shoes. Leveraging the capabilities of additive manufacturing, we designed a hybrid component using dual-material 3D printing to combine structural rigidity and ergonomic flexibility. Rigid PLA (Polylactic Acid) forms the front portion of the protector to resist water and impact, while soft TPU (Thermoplastic Polyurethane) forms the upper collar that wraps comfortably around the ankle area for secure attachment and flexibility.

Previous research has explored multi-material 3D printing in fields such as medical prosthetics, flexible consumer electronics, and wearable sensors. However, its application in sportswear—particularly for modular and performance-enhancing components—remains underdeveloped. This project explores that intersection, aiming to demonstrate how hybrid-material design principles and 3D printing can deliver practical solutions in the consumer footwear domain.

Previous research has explored medical prosthetics, flexible consumer electronics, and wearable sensors. However, its application in sportswear—particularly for modular and performance-enhancing components—remains underdeveloped. This project explores that intersection, aiming to principles and 3D printing can deliver practical solutions in the consumer footwear domain.

Materials

Materials

Two distinct materials were selected to achieve functional contrast and address the competing needs for rigidity and flexibility in the splash protector design:

- PLA (Polylactic Acid): A biodegradable thermoplastic derived from renewable resources, PLA was chosen for the front portion of the protector due to its high stiffness, ease of printing, and water-resistant properties. It provides the structural integrity necessary to block water splashes and maintain the form of the protector during motion and external impact.

- TPU (Thermoplastic Polyurethane): TPU is known for its flexibility, elasticity, and wear resistance. It was used for the upper portion of the splash protector to ensure that the device could comfortably conform to varying ankle shapes while maintaining a secure fit on the shoe. TPU’s soft, rubber-like characteristics made it ideal for contact with the user’s skin or sock.

Due to limitations in the available 3D printers at the UW Makerspace, the PLA and TPU components were printed separately. The Bambu X1C printer was utilized for both materials in separate sessions, using Bambu Studio for slicing and G-code generation. The inability to print both materials simultaneously introduced workflow constraints, including increased print time and the need for post-processing to assemble the final hybrid part. Support structures were required for TPU due to its flexible nature, and their removal was carefully handled to avoid damaging the softer features.

Methodology

The methodology consisted of four main phases: scanning, design, slicing and printing, and iterative prototyping.

Measurement: The shoe’s geometry was captured using the Creality Raptor X 3D scanner. The scanner utilizes structured light technology to produce a detailed mesh model, accurately replicating the curvature and dimensional profile of the sports shoe. This data served as the foundation for the CAD modeling stage.

Fig1: 3D scan of right hoe

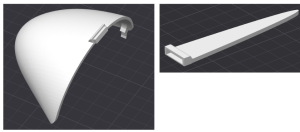

CAD Design: The mesh obtained from scanning was imported into SolidWorks and Fusion 360, where it was cleaned and segmented into functional zones. Using the scanned contours, a 3D sketch was created to wrap around the toe area. Surface lofting techniques were then applied to model the upper TPU section. After verifying surface continuity and wall thickness, solid bodies were generated from the surfaces. The design was then partitioned into rigid and flexible zones based on material requirements.

Fig2: CAD model

Slicing & Printing: The models were sliced using Bambu Studio. Due to the unavailability of a dual-extrusion printer capable of handling both TPU and PLA simultaneously, each material was printed in a separate session using the Bambu X1C. Layer height was set to 0.2 mm for a balance between detail and print speed. Custom supports were designed and manually added for the TPU component due to its tendency to deform under unsupported sections. Careful handling was required during support removal to prevent structural damage.

Design Iteration: Two main design iterations were produced:

- Design 1: Integrated a slot within the wall of the protector to allow the TPU section to slide into place. This design faced challenges such as a shallow slot depth, inadequate interlocking, and difficulty in removing supports from the flexible TPU section.

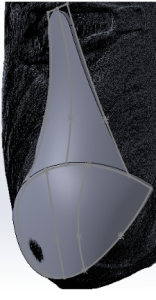

Fig 3: Design 1

- Design 2: Incorporated a revised slot mechanism and reshaped upper geometry for improved fit and alignment with the shoe. These adjustments enhanced usability, structural bonding, and wearer comfort, making it the final version used for testing.

Fig 4: Design 2

Results and Discussion

The final prototype is made using design 2 which demonstrates both functional performance and user-friendly design. It was easy to attach and detach from standard sports shoes, offering effective splash protection in simulated wet environments. The rigid PLA front section successfully maintained its shape under minor impacts and deflected water away from the mesh toe area of the shoe. Meanwhile, the flexible TPU upper provided a comfortable and secure wrap around the ankle, accommodating various foot shapes without causing irritation. The integration of two materials allowed for enhanced ergonomics, balancing structural support with flexibility. However, the use of separate printers for PLA and TPU introduced workflow limitations, including increased printing time and the need for precise post-assembly alignment. Despite these constraints, iterative design adjustments—particularly in slot geometry and upper curvature—significantly improved the fit, usability, and overall effectiveness of the splash protector.

Figure 5: Final Prototype

Conclusions

This project demonstrated a successful application of dual-material 3D printing for solving real-world wearable problems. The splash protector is customizable, lightweight, and ergonomic—qualities essential for sportswear. The use of TPU and PLA allowed a balance between comfort and protection. Future improvements include integrating printing into one platform and optimizing TPU support removal.

Acknowledgement

We thank UW-Madison Makerspace for access to 3D printing equipment and tools. Special thanks to the course instructors for guidance throughout the project.

References

- Davenport, J., Materials Transformation Center, personal communication.

- Chung, C.I., Barr, R.A., U.S. Patent 4,405,239 (1983).

- Somers, S.A., et al., SPE-ANTEC Tech. Papers, 41, 222 (1995).

- Spalding, M.A., et al., SPE-ANTEC Tech. Papers, 52, 792 (2006).