Battery-Free 3D-Printed Balance with Metamaterials

Zebang Zhang, Li Yu

Abstract

This project explores the use of additive manufacturing to develop a battery-free, metal-free mechanical scale that operates using deformation-based mechanisms instead of conventional electronics. The scale is manufactured with FDM and DLP 3D printing techniques, employing TPU and high-resolution resins to realize architected structures. There are two special patterns we applied here as the core components for the scale function: an auxetic pattern fabricated to provide uniform deformation under load, and a Kirigami pattern fabricated to exploit buckling for large deflection at low force. Weight measurement is read by correlating the visible shift in either design to a pre-calibrated force–displacement curve—no sensors, wires, or batteries required. The result is a lightweight, maintenance-free, MRI-safe scale tailored for settings where electronics are impractical or electromagnetic interference is a concern.

Introduction

Conventional weighing devices typically rely on metal springs, strain gauges, or piezoelectric sensors to turn force into an electrical signal with metal. While effective, these systems require batteries, electronics, and often metallic components that can limit their use in environments such as MRI rooms, where electromagnetic interference must be avoided. Also, the conventional scale has a big size that cannot fit into a wallet, which is inconvenient to carry. In addition, conventional mechanical sensing systems often demand precise machining and careful calibration, driving up cost and complexity. These drawbacks invite a fresh approach: passive, “mechanically intelligent” structures that sense load without a single line of circuitry.

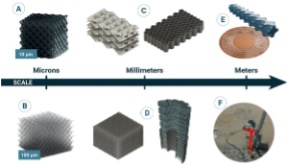

Additive manufacturing (AM) offers a unique opportunity to redesign such systems by using the fabrication of architected materials—materials whose performance derives more from their internal geometry than from their bulk composition. Within this category, metamaterials have attracted increasing attention for their ability to exhibit exotic mechanical properties not found in naturally occurring solids. Engineers can grant bulk materials nurtured properties by designing internal structures with specialized geometries—such as re-entrant lattices, rotational hinges, or kirigami-inspired cut patterns.

An example of such properties is the negative Poisson’s ratio, which is calculated by dividing the lateral strain with the axial strain. Auxetic structures of negative Poisson’s ratio often possess enhanced energy absorption, improved fracture resistance, and better load distribution. In this project, we integrated this principle into the design of the architected material of a scale. This auxetic pattern allows the structure to uniformly deform under a certain load and return to its original shape with minimal residual strain, making it ideal for applications that demand repeatable, elastic behavior.

| Figure 1. Materials with internal structure engineered at different scales [1]. |

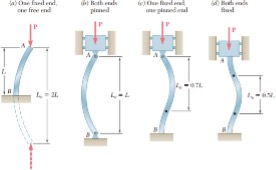

Another geometric feature we harnessed is the buckling effect. Buckling is something engineers usually would try to avoid in structural systems. However, controlled buckling in metamaterials can be used to introduce nonlinear deformation behavior at specific load thresholds. We found that kirigami patterns are one of the designs that deliberately buckle materials under applied load. As a result, the structure will achieve significant deflection with relatively little force, behaving like a mechanical fuse or spring that regulates response.

Figure 2. The process of the buckling effect [2].

By combining these two architected behaviors—auxetic deformation and controlled buckling—we demonstrate a battery-free, metal-free , and solely 3D printed mechanical scale. The device utilizes deformation of printed features to indicate applied load, providing a passive measurement system that is lightweight, low-maintenance, and MRI-safe. This project showcases how advanced geometric design can be used to fabricate mechanically responsive systems for specialized sensing applications.

Methodology

Pattern Design

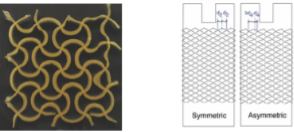

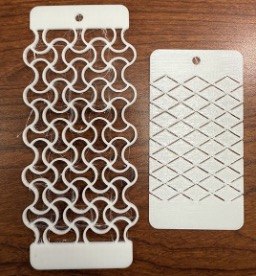

After researching several metamaterial related papers, we decided to design the scales based on the following two interesting patterns: auxetic lattice pattern and kirigami metasurface pattern (Figure 1). The kirigami pattern stays flat and stiff until a threshold is reached, then the cut portions fold out, providing a lot of deflection with relatively small added force; while the auxetic pattern could contract uniformly as load increases in a relatively wide range.

Figure 3. Auxetic (left) and kirigami (right) patterns utilized for the scale design [3,4].

Manufacturing

One scale for each design was fabricated using FDM printing using TPU, a flexible thermoplastic. All designs rely on mechanical deformation, with no embedded electronics or metals. Architected geometries and kirigami cuts were modeled in CAD to achieve tailored force–displacement behavior. These auxetic patterns expand or contract uniformly under load, offering a predictable, tunable deformation profile. The uniform deformation makes them ideal for scales that require a gradual, readable mechanical response to increasing weight. TPU is selected for its elasticity and resilience, ensuring the structure can deform and recover repeatedly without plastic failure. The kirigami structures were engineered to produce large vertical displacement in response to relatively small loads, making them particularly useful for compact scales or low-weight applications.

Functionalization

After being fabricated, the scales went through tensile testing for calibration. Weight is measured by correlating the amount of vertical or lateral displacement to the applied load, with deformation tracked using 3D-printed force indicators that were put alongside. It is anticipated the scales should deform smoothly and uniformly without failure or permanent deformation. Calibration will involve applying known weights and measuring the corresponding deflection through tensile or compression tests to establish a force–displacement curve for each design.

Results and Discussion

Custom Balance Structure

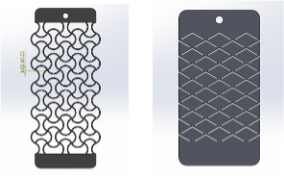

Figure 4 shows the eventual design of the scales using the auxetic and kirigami patterns. It’s essentially a hybrid metamaterial: when you push down on it, it compresses evenly and when you release it, it expands back to its original shape. The auxetic design had a dimension of 144 mm x 63.5 mm (H x W), and the kirigami design had a dimension of 99 mm x 52 mm. As a reference, the size of a credit card is 85.6 mm x 53.98 mm. Thus the sizes of the scales were just a bit larger than a credit card, making them a great fit for portable usage.

Figure 4. The eventual auxetic (left) and kirigami (right) designs.

The kirigami could give a soft response (through buckling) for sensitivity, and the auxetic lattice provides a backbone that is highly elastic and returns to shape reliably. Therefore, each device will compress under an object’s weight like a spring scale and then recover when the weight is removed. We went through a few design iterations to calibrate the geometry such that the deflection is proportional to the force (within a certain range), allowing us to measure weight by how far the top moves. Essentially, we created a spring scale out of plastic geometry instead of metal.

Manufacturing

We initially attempted to use DLP printing to fabricate the balance with resins, but the soft materials from Formlabs do not provide adequately good properties. Thus instead, we casted FDM printed molds with various stiffness silicon rubber as the soft polymer to fabricate the desired shape. Besides, we also tried to put the yellow kevlar fiber into the rubber to limit its stiffness and avoid breaking. However, we realized that removing the mold without damaging the part, avoiding air bubbles in thin features was very difficult.

Figure 5. The initial manufacturing attempts. From left to right, the images are respectively DLP-printed kirigami pattern, casted kirigami pattern, and casted auxetic pattern.

Therefore, for our final prototype, the fabrication switched to FDM printing with TPU filament (Figure 6). As TPU is a flexible, stretchable, and tough elastomer that can be used in standard filament printers, we considered it a perfect material meeting our needs. We printed the entire balance structure as a single piece, which is a big advantage – no assembly demanded or bonding between different parts. With this TPU metamaterial structure, the device behaves like a spring made of rubber. When you press on it, it compresses smoothly; when you remove the force, it springs back to exactly the same shape. We cycled the device many times to ensure the material would not fatigue quickly. TPU’s resilience gave us confidence in the device’s durability.

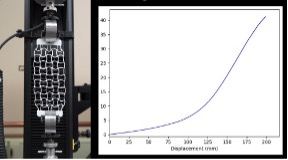

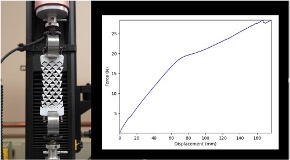

Figure 6. The final prototypes made by FDM printing using TPU. Mechanical Testing

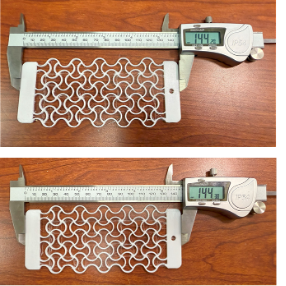

Figure 7. shows the force-displacement curves for the two designs. It could be observed that both structures deformed uniformly within a certain initial range; the kirigami cuts buckled as expected, auxetic cells compressed, then the entire piece returned to flat shape. As the force increased, you can see the kirigami pattern started to buckle slightly and the auxetic lattice compressed. The deformation was smooth and uniform – there was no sudden failure or uneven bending. In this testing, the maximum force applied went up to 40 N, and no failure occurred. After removing 40 N load, we measured the devices’ length to see if it was permanently deformed (Figure 8, 9). The permanent deformation was essentially negligible – only 0.1% rate of elongation after enduring the 40 N load. It should be noted such a high load was more of a stress test beyond the intended usage. For practical use as a balance, we determined the comfortable measurable load range to be 0–20 N.

Figure 7. Force-displacement curves of the auxetic (top) and kirigami (bottom) scale.

Figure 8. Comparison of the auxetic scale’s natural length before (top) and after (bottom) enduring the 40 N load.

Figure 9. Comparison of the auxetic scale’s natural length before (top) and after (bottom) enduring the 40 N load.

Final Prototype and Usage Scenario

Figure 10 shows the photographs of our final prototype. This is a multi-material printing object. To use this balance, a user simply places an object on the top surface. The weight of the object causes the top platform to sink down a bit. With the help of the plastic measurement bars on the side, the user would be able to read the weight of the object easily. The only thing that needs to be done is to add a hook to hold the thing to be weighed.

Figure 10. Final prototype of the auxetic (top) and kirigami (bottom) scales.

Conclusions and Outlook

This project successfully demonstrated the feasibility of using architected materials and multimodal additive manufacturing to create a battery-free, metal-free mechanical scale. By combining auxetic structures and kirigami designs, we achieved a functional device capable of reliably translating applied load into visible mechanical deformation. The resulting prototype is lightweight, low-maintenance, and compatible with environments where electronics or metals are restricted, such as MRI suites. This work highlights the potential of geometry-driven design in developing passive, mechanically intelligent devices. Our designs still have potential to be further developed. For example, there might exist extended material selections and functioning patterns, which could increase the measuring range of the scales. Moreover, additional elements could be integrated, such as optical components for assisting the readout after weighing.

References

[1] https://multiscalesystems.com/lab-notes.

[2] https://www.slideserve.com/noel-nielsen/buckling-of- columns-13-1-13-3.

[3] Liu, J., Gu, T., Shan, S., Kang, S.H., Weaver, J.C. and Bertoldi, K. (2016), Harnessing Buckling to Design Architected Materials that Exhibit Effective Negative Swelling. Adv. Mater., 28: 6619-6624. https://doi.org/10.1002/adma.201600812

[4] Babaee, S., Pajovic, S., Rafsanjani, A. et al. Bioinspired kirigami metasurfaces as assistive shoe grips. Nat Biomed Eng 4, 778–786 (2020). https://doi.org/10.1038/s41551-020-0564-3