Project Overview:

The purpose of this project is to perform testing on an innovative new additive manufacturing technology. Traditional extrusion based printers utilize heaters to melt the filament in the nozzle. Not only is this method inefficient, but the speed at which the filament is melted limits print speeds. It is theorized that heating the filament through viscous heating will not only be more efficient, but also cause much faster melting. In this project we will perform preliminary testing to gather data on the effectiveness of viscous heating to accelerate melting in additive manufacturing.

Experiment Design:

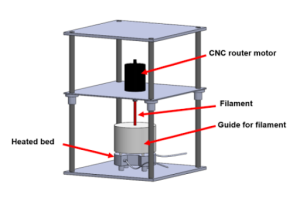

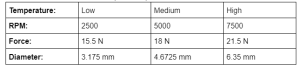

This experiment will be performed on a simple test setup pictured below in Figure 1 [1]. The components include a 3-level metal frame, a heated bed, filament guide block, CNC router motor, and the filament itself. The test will measure the weight of each filament specimen before and after the experiment to determine the rate of melting for each configuration. The experimental procedure begins by setting the temperature of the heated bed. Next, to set the RPM’s of the given experiment, the voltage to the motor is adjusted. After ensuring the build plate is clear, the filament guide and the filament itself are placed. Lastly, the filament is lowered while turning on the motor. The experiment will last 60 seconds from the moment the filament touches the heated bed. Many variables will be tested in this experiment, as shown in Table 1 below.

Figure 1: Computer model of experimental setup

Table 1: Experiment parameters to be tested

Preliminary Testing:

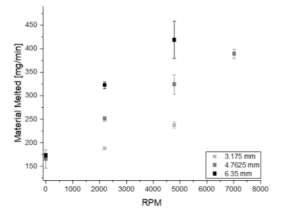

The preliminary testing done on this project has already yielded important results that are depicted in Figure 2 [1]. At low RPM where conduction dominates the heat produced in the nozzle, all diameters of filament melt at similar speeds. As the RPM is increased, all diameters can see increased material melting caused by viscous heating. Larger diameter filaments see an even larger benefit than smaller diameters from using viscous heating. It can be seen that viscous heating can vastly improve melt speeds, especially when used with larger diameter filaments.

Figure 2: Results of initial testing

End Goal:

The data being collected from this experiment will help to aid in the design and understanding of a viscous heating extrusion printer. Further experiments will later be run with a finalized prototype that is currently being constructed.

References

[1] T. Osswald, A. Roman, ‘Accelerating FFF Printing via Viscous Heating’, University of Wisconsin-Madison, 2022.