Christina Harmon, Christopher Lawrence, Justin Tan, Oliyad Dibisa, Tommii Zeng

Introduction

Polyethylene (PE) is a thermoplastic polymer with a variable crystalline structure and a vast range of applications depending on the type. PE is a popular material due to its affordability, machinability, and compatibility with other materials. High-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE) are two types of PE. HDPE has molecules that are packed together tightly, have a linear structure, and are opaque. HDPE is strong, has a high tensile strength, rigidity, and impact resistance. LLDPE is also strong and is a substantially linear PE with numerous short branches. However, PE has been shown to be quite challenging to use when it comes to 3D printing. Specifically, when printing with HDPE and LLDPE, the material is unable to stick to the printing bed. Additionally, PE suffers unacceptable warpage and shrinkage [1].

Vitrimers are a new class of polymers that combine the properties of thermoplastics and thermosetting materials: they behave like cross-linked materials at service temperature while being processable at elevated temperature due to the presence of dynamic cross-links. Vitrimers feature dynamic covalent crosslinks that do not dissociate in the course of the exchange reaction. However, despite a constant degree of crosslinking, these materials can flow under the action of heat depending on the kinetics of the exchange reaction [2]. Vitrimers are beneficial as they are able to achieve a compelling balance of robust mechanical properties and processability [3]. At high temperatures, they can flow like viscoelastic liquids, while at low temperatures the bond-exchange reactions are immeasurably slow (frozen) and the vitrimers behave like classical cross-linked materials at this point [3].

Vitrimers are a promising material and combining the benefits of these vitrimers with PE, by utilizing PE vitrimers, in the 3D printing process could potentially resolve the challenges that occur when 3D printing with PE alone. Thus, the first objective of this project is to develop a successful method to 3D print with HDPE and HDPE vitrimers. The second objective is to 3D print rectangular specimens of each material to use for warpage tests, shrinkage tests, and strength tests (printed at 0°, 45°, and 90°) in order to compare and characterize the properties of each material. If it is found that HDPE is unable to be printed with, then LLDPE will be used instead.

Preliminary Design

To better understand the feasibility of printing PE, the warpage, shrinkage, and strength of the materials will be characterized. Since HDPE Vitrimer is a newly developed material, filaments (commonly used in FFF 3D printing) are not able to be found. Thus, the Cosine extrusion 3D printer will be used to print specimens for both materials for the tests.

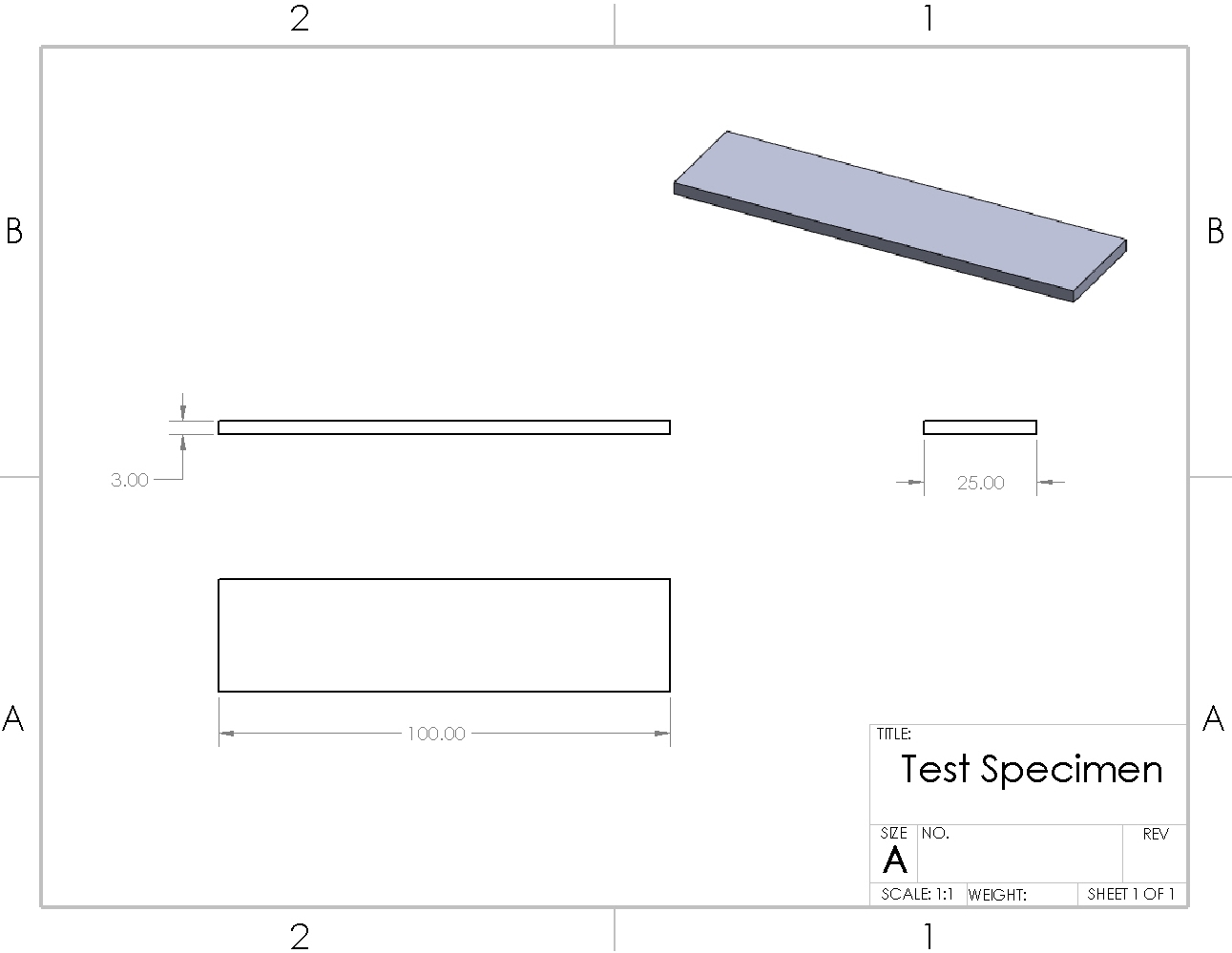

Test specimens are designed with dimensions of 100mm×25mm×3mm. A standard dog bone-shaped test specimen will not be used for this application to eliminate the stress concentrations introduced by the recessed shape. Multiple test specimens will be printed for each material to complete the following tests.

Warpage tests will be performed by placing specimens on a flat surface with one side pressed firmly onto the surface. The warpage will be determined by measuring the vertical distance between the flat surface and the point of the highest deflection of the specimens.

Shrinkage tests will be performed by taking pictures of the printed parts in the print bed immediately after the printing process and after 24 hours when the parts have cooled down. The images will be taken with a scale in the background which can be later processed by software ImageJ (or similar software) to measure the parts’ initial and final dimensions. Alternatively, the measurement can be done manually with a caliper.

Strength tests will be performed by printing the specimens at orientations of 0°, 45°, and 90°. Tensile tests will be performed on the specimens using an Instron Universal Testing Machine 5967 with a 30kN load cell. Lastly, another set of specimens with the same orientations will be printed and heat-treated in an oven below their melting temperatures to enhance interfacial adhesion between the printed layers. Additional tensile tests will be performed on these specimens and the effect of heat treatment on the material will be evaluated.

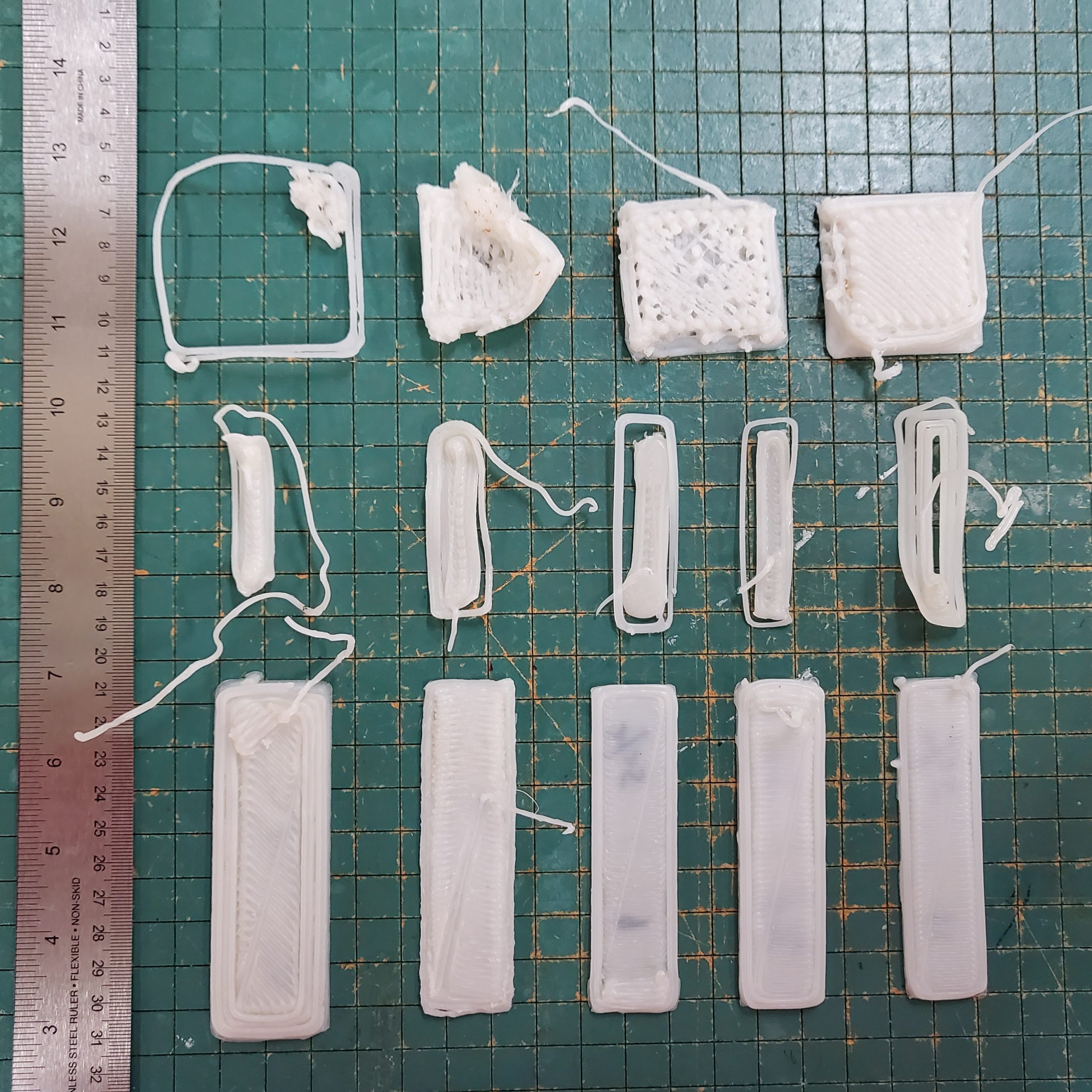

Proposed First Print Trial

Before any of the above tests can be performed, the screw-based additive manufacturing machine must be properly tuned to effectively print the materials. This machine was produced by the company Cosine and uses a single screw extruder to melt polymer pellets. This machine is able to print any polymer if provided with the correct settings. However, there are no predetermined settings to print either HDPE or HDPE Vitrimers. To remedy this, numerous tests will be run to determine the correct settings of the machine to optimize the printability of the system. Due to the complexity of the machine, and the amount of different tunable parameters, a significant amount of time will be spent on fine-tuning the machine to print these materials.

After the machine is tuned, the testing specimens will be printed. There will be two sets of print specimens, plain HDPE and HDPE vitrimers. These specimens will then be used in the tests described above. It is hypothesized that HDPE vitrimers will have less warpage and less shrinkage compared to the plain HDPE specimens due to the presence of cross-links in the material. These cross-links have been shown to lower the degree of crystallinity of the material. Similarly, lower mechanical anisotropy is expected for the vitrimer specimen due to the higher bond strength between layers. Finally, a post-curing process will be performed in the samples to further improve bond strength. This process will be performed at the melting temperature of the material (135 °C). However, the plain HDPE will most likely deform significantly due to the low melt strength. In contrast, the HDPE vitrimer has a high melt strength due to the cross-links present in the material, which can make the post-curing process possible.

References

[1] Spoerk, Martin, et al. “Material Extrusion?Based Additive Manufacturing of Polypropylene: A Review on Ho]w to Improve Dimensional Inaccuracy and Warpage.” Journal of Applied Polymer Science, vol. 137, no. 12, 2019, p. 48545., https://doi.org/10.1002/app.48545.

[2] Van Zee, Nathan J., and Renaud Nicolaÿ. “Vitrimers: Permanently Crosslinked Polymers with Dynamic Network Topology.” Progress in Polymer Science, vol. 104, 2020, p. 101233., https://doi.org/10.1016/j.progpolymsci.2020.101233.

[3] Jurowska, Anna & Jurowski, Kamil. (2015). Vitrimers – The miracle polymer materials combining the properties of glass and plastic?. CHEMIK nauka-technika-rynek. 69. 392-394.