Overview

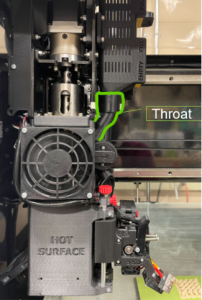

Additive Manufacturing (AM) techniques have risen to the forefront of engineering given their capacity to reproduce intricate design features that would otherwise be difficult to attain through traditional subtractive manufacturing processes [1]. One of the branches of extrusion additive manufacturing is screw-based extrusion systems, which can use material in pellet-form that is too brittle to be made into filament. In our project, the printer that will be optimized has both a screw extrusion system and filament extrusion system, as shown in Figure 1. The benefit of this type of printer is that it can extrude two materials, one of which is used as a support structure.

However, the pain point of employing this 3D printer to generate any model is the discontinuous feeding due to the clogging issue of pellets in the feeding zone. The purpose of this project is to improve the performance of the feeding zone of the single screw extrusion printer to avoid the printing failure due to the discontinuous extrusion.

Funnel flow such as the flow of pellets through this throat is typically obstructed either due to ratholing or due to bridging. Ratholing is the formation of a central column over the exit hole whereby all material is resting along the walls and not flowing through the hole. This is usually encountered in fine-grain and/or cohesive materials that tend to stick to each other or that have high interparticle friction. Bridging, on the other hand, is the formation of an arch over the exit hole whereby a dome supports the material in the funnel instead of allowing it to flow. This can occur with particles of high cohesiveness or with particles that can lock together geometrically [2]. Bridging through geometric locking may cause interrupted flow in this application as plastic pellets usually have edged geometry and are relatively large.

There are two additional hypotheses for what the fundamental reason is behind the pellets getting stuck. One is the surface finish of the printed throat is not smooth enough, which gives more friction during the pellets feeding. The other one is that the design of the throat is not suitable for the pellets with the sharp shapes.

Manufacturing considerations

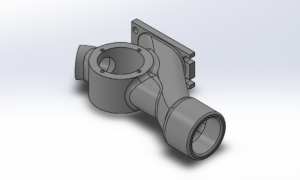

As our work is based on the design optimization of the throat, the original design was received directly from Fused Form, as shown in Figure 2. To determine the cause of the pellets getting stuck, our work will be mainly separated into two steps.

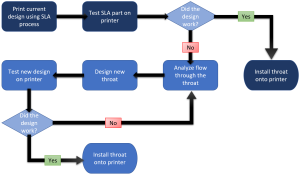

We will print the part with a Stereolithography (SLA) printer first. The reason for it is that the parts printed by SLA are chemical bonds instead of mechanical bones generated by extrusion based AM technologies, like Fused Filament Fabrication (FFF)[3]. The chemical bonds result in a better surface finish. Additionally, the black color of the current design makes it tough to analyze how the pellets flow through the throat. The transparent material will be selected to contribute to the observation and analysis of pellet flow in the throat. If the first proposed solution works, we will focus on how to install the throat from SLA on the single screw extrusion printer.

Our second plan is to improve the design of the throat. The feed flow observed from the transparent SLA part will play a big role on this step. More specific information will be provided after the performance from the first solution. A flow chart of the test plan is outlined in Figure 3.

Preliminary Work:

One concern with using the SLA printer was resin being trapped inside the model. A preliminary model was printed at 30% scale to see whether the resin would be trapped on Formlab printer at Makerspace. The resin was not trapped between the supports and our object as shown in Figure 4.

Another concern with the SLA printer is that there were a couple of supports inside the throat which is hard to remove. Another throat was printed in a different orientation designed to eliminate the internal throat supports, as shown in Figure 5.

The second prototype was sliced in a more upright position, which eliminated the need for internal structural support. Further work includes printing a full size throat using the exact same orientation, and determining if the structural strength is the same.

To make the throat transparent a clear resin will be used on the FormLab printer. The transparency of the part is not high enough for our purpose to observe the feed flow so it will be polished after the print. Some preliminary research on how to polish the surface shows that sanding the part initially at a rough grit all the way up to 2500-4000 grit can produce a clear part. Additionally, an acrylic clear coat spray can be applied to increase the transparency [4] [5].

An initial attempt at increasing the transparency of a part printed in clear resin was performed using 2500 grit sandpaper. Acrylic clear coat spray was unavailable, so superglue was used instead. Using a clear fluid to resurface the part provides a smooth exterior which improves transparency. Practically, the fluid should solidify and remain clear without being sticky in order to provide similar funnel characteristics to the original funnel.

References:

- Ngo, T. D., Kashani, A., Imbalzano, G., Nquyen, K. T. Q., & Hui, D. (2018, June 15). Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Redirecting. Retrieved February 28, 2022, from https://doi.org/10.1016/j.compositesb.2018.02.012

- “Solve or Prevent Poor Flow,” Jenike & Johanson. https://jenike.com/solutions/solve-or-prevent-poor-flow/ (accessed Mar. 02, 2022).

- How 3D printing direction/orientation affects strength? FacFox Docs. (2019, November 26). Retrieved February 28, 2022, from https://facfox.com/docs/kb/how-3d-printing-direction-orientation-affects-strength

- Polishing Clear Resin for a transparent finish. FormLabs. (n.d.). Retrieved February 28, 2022, from https://support.formlabs.com/s/article/Polishing-Clear-Resin-for-a-Transparent-Finish?language=en_US

- Guide to clear 3D printing. Formlabs. (n.d.). Retrieved February 28, 2022, from https://formlabs.com/blog/3d-printing-transparent-parts-techniques-for-finishing-clear-resin/