Low Cost Passive Sixth Finger Prosthetics

Adam Homel and Sarvesh Sakthivel

Polymer Engineering Center, University of Wisconsin-Madison, USA

Abstract

Personalized prosthetic fingers typically range from $2,000 to $20,000 for people with disabilities, especially due to the motorization of a moving joint. This reduced accessibility minimizes the market. Additive manufacturing enables rapid prototyping of custom components at a low cost. Combining the passive characteristics of prosthetic devices by Arm Dynamics and joint mechanisms of Dani Clode’s Third Thumb design, a low cost, 3D printed passive sixth finger prosthetic was created for all users, including users with disabilities. This initial prosthetic design is the first in a long line to provide increased utility of the hand at a low cost. After multiple iterations of the prosthetic finger and the hand grips, a final prototype was developed that allows for the independent use of the four fingers not involved during prosthetic use. Although there are many shortcomings of the initial prototype, future directions and improvements can be made to keep the prosthetic at a low cost while still allowing for effective body augmentation.

Introduction

Additive manufacturing, also known as 3D printing, is a method of manufacturing that enables rapid prototyping of custom components. When combined with Computer-Aided Design (CAD) software, users can seamlessly go from initial concepts to creating functional and cost-effective prototypes. Often, this process is less expensive and quicker for initial models than traditional manufacturing methods. One of the biggest advantages of 3D printing is its capacity to fabricate complex geometry that may be impossible to achieve using other techniques. This unique capability has far-reaching implications across a variety of fields. Healthcare is one of these fields as the demand for personalized solutions continues to grow.

A strong example of the impact of additive manufacturing can be seen in prosthetics. According to Prime Care Prosthetics, the cost of personalized prosthetic fingers typically ranges between $2,000 and $20,000 [1]. This represents a large financial burden for many individuals and highlights the issues of accessibility and affordability for those who need prosthetics. The high cost of these devices prevents those in need from obtaining high-quality, functional prosthetic devices that could significantly improve their quality of life.

In response to this financial burden, the following research question was posed: Can a lower cost passive sixth finger prosthetic increase the utility of the hand and return appendage use to people with disabilities? While there have been previous attempts to develop both electronically controlled (active) and body-powered (passive) prosthetic devices, none have achieved a level of affordability that would make them widely accessible to the public.

The primary goal of this project is to address this gap by designing and developing a low-cost, passive prosthetic finger through the use of additive manufacturing. By leveraging the inherent strengths of 3D printing, this project seeks to create a practical and accessible solution to enhance hand functionality for individuals with disabilities and those who seek more use out of their hands.

Background and Motivations

To better evaluate the market for available prosthetic devices, research was conducted to analyze what solutions already existed. In doing so, two different sources presented themselves. The first was a company that manufactures passive prosthetic devices. This company is Arm Dynamics, who offer a whole host of options from fully passive prosthetics to electrically powered prosthetics. To get a better idea of the kind of benchmark that exists in the market, the body-powered prosthetic option was taken as the case study. As can be seen below in Figure 1, a person is being fitted with a body powered, passive prosthetic device.

Figure 1: Body-Powered Passive Prosthetic Device by Arm Dynamics.

This device allows the user to strap it onto their wrist and use their existing joints and muscles for articulation. This provides the user with a functional thumb with no concern about electronics present. The limiting factor about this device is that it likely needs to be made custom for each user as hands come in all shapes and sizes. Doing this, especially with metal manufacturing, begins to get costly quickly which will be reflected in the final price of the prosthetic.

Another project that was interesting in this application was the Third Thumb by Dani Clode. Dani Clode began the Third Thumb project during her graduate studies in 2017. Today, scientists are working with Dani Clode to conduct research on how the brain adapts to augmentation of the hand in the Plasticity Lab in the University College London as well as Cambridge University [6]. Figure 2 and Figure 3 below display the Third Thumb’s functions and variations.

Figure 2: Dani Clode’s Third Thumb on varying hand sizes and shapes.

Figure 3: Alternate designs of Dani Clode’s Third Thumb.

Contrary to the passive prosthetic devices created by Arm Dynamics, the Third Thumb is mechanically powered. It is controlled by the movement of the user’s toes. This addition to the user’s hand does not only fix or replace an appendage, but seeks to extend the ability of the human hand [7]. In addition, since the thumb extension is developed with the use of 3D-printing, it entirely relates to the purpose of this design project. By combining the two main characteristics of the Arm Dynamic prosthetic and Dani Clode’s Third Thumb, a new passive sixth finger prosthetic design can be developed to meet the objectives discussed earlier: to create a practical and accessible solution to enhance hand functionality.

Initial Concepts

To prove the viability of 3D printed prosthetic devices, initial sketches were drawn. These resemble Dani Clode’s Third Thumb as a concept, but with the exception of it being a fully passive device that only relies on the body’s own power, like the Arm Dynamics model. The idea for the first model of this project was to make a prosthetic device for individuals who have full use of their thumbs as the user’s thumb would provide the pulling force on the fishing line to bend the thumb. The idea for manufacturing this was to print the finger out of TPU for flexibility and articulate its joints by using a fishing line. This fishing line would then be routed across the back of the user’s hand and connected to the user’s other thumb.

The hand grips were designed to be held in place using rubber bands. They were sketched with the curvature of the user’s hand in mind. They also needed to be connected to the finger via a joint that would only articulate about ninety degrees. The other main goal of the hand grips were to make sure that the fishing line was routed to not touch the user’s hand.

Prototypes

Many iterations of prototypes followed the sketches that were drawn as an initial springboard for design ideas. Both the finger and the hand grip went through three separate iterations. Tolerancing the pieces together properly was the largest challenge as some parts needed a snug fit, while others needed to be looser.

Finger

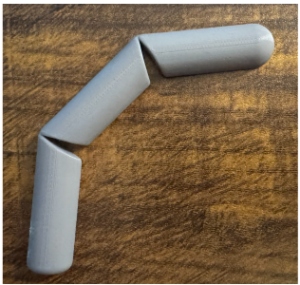

The finger was modeled in SolidWorks using easily editable design practices for future changes. The initial design was a proof of concept using TPU for AMS on the Bambu Lab X1 Carbon 3D printer. TPU for AMS was far too rigid for this application and did not bend or spring back nearly enough. However, the prototype model still provided great insight into necessary dimensional changes and other features that needed to be added. This iteration planned to use a ball joint to articulate the finger around, but this proved to be too many degrees of freedom with future conceptualization. The first prototype is shown in Figure 4 below.

Figure 4: Initial Finger Proof of Concept Prototype.

The next iteration of the finger changed its shape and curvature to be more human-like. It had larger angles and gaps between the segments of the finger and also integrated a slot for the fishing line in to move it. This iteration was printed out of TPU 95A HF, which provided the necessary material properties for this application. Additionally, a new single plane hinge design was attempted in this iteration, but incorrect dimensioning led this to being half the size required. In attempting to glue the two halves of the finger together, it was determined that this approach would not yield a good bond between them. The idea with splitting the design was to make the TPU easier to print and not require any support, as this is challenging to remove from TPU parts. The second prototype of the finger is shown in Figure 5.

Figure 5: Second iteration of the Finger Prototype.

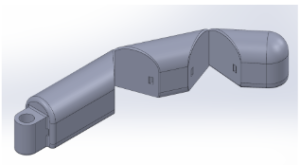

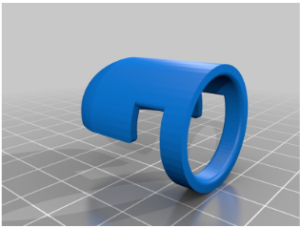

Finally, the learnings from the second iteration of the finger were integrated into the final prototype. It joined the two halves of the model together into one unit that the fishing line could be threaded through. It also resized the hinge to fit with the hand grip that was being developed simultaneously. This final prototype fit together well with the other pieces of the design and was durable throughout testing. A CAD model of the resulting prototype is shown in Figure 6 below.

Figure 6: Final iteration of the Finger Mechanism.

Hand Grips

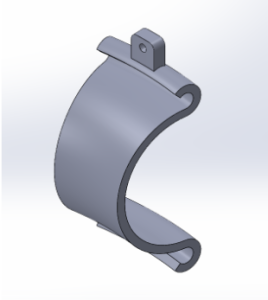

The two hand grips in the functional prototype were modeled in SolidWorks with the intention that iterations would be needed to modify the design. All dimensions are easily altered. PLA was determined to be the printing material as it has the necessary strength, processability, and ease of prototyping for this project.

The first iteration of the hand grip was mainly to check the compatibility of each grip with the shape of the hand. In order for the prosthetic to work as easily and effectively as possible, the hand grip had to sit comfortably on the user’s hand. Additionally, curves on the top and bottom of the hand grips were added to hold the rubber bands. These rubber bands will connect the two hand grips together around the user’s palm. Figure 7 below displays the first iteration of the hand grips.

Figure 7: First iteration of the two hand grips.

Once it was confirmed that the dimensions and curvature of the first iteration of the two hand grips were comfortable for the user, the next step included adding guides for the fishing line that will flex the prosthetic finger and the axle structures to allow for the rotation of the prosthetic finger. These axles were found on GrabCAD, created by the user Yauhen [8]. Figure 8 below displays the second iteration of the hand grips. Figure 9 below displays the printed axles.

Figure 8: Second iteration of the two hand grips.

Figure 9: Printed axles by Yauhen on GrabCAD.

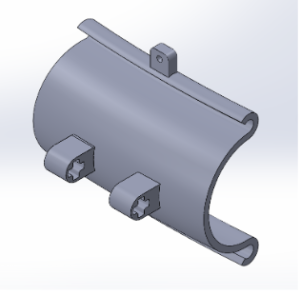

After the second iteration, the hand grips and the axles were tested for press fit ability and the required rotation. To accommodate for the prosthetic fingers material around the axle, the axle structures on the hand grip were adjusted to hold the axle farther from the base of the hand grip. Additionally, the axle sizes were scaled in size and length to determine the best press fit into the axle structures in the hand grips. As a result, Figure 10 and Figure 11 below display the final CAD models of the hand grips.

Figure 10: Final iteration of the first hand grip.

Figure 11: Final iteration of the second hand grip.

Final Prototype

The final prototype of the sixth finger prosthetic includes the changes made to accommodate the fishing line hole placements, the correct size of the finger segments, the comfort of the hand grips, the fitment between the finger and the hand grip, and the correct tolerance on the axle. In addition to the finger, the hand grips, and the axle, a thumb cap was printed from Thingiverse by Clbwright [9]. Figure 12 below displays the thumb cap model.

Figure 12: Printed thumb cap by Clbwright on Thingiverse.

In total, four different materials were used to create the first functional prototype. These materials include TPU 95A HF, PLA, natural rubber latex, and nylon. TPU 95A HF was used to print the finger and the thumb cap. PLA was used to print the hand grips and the axle. The two rubber bands that were used to fix the hand grips to the user’s hand were made of natural rubber latex. Finally, the fishing line used to articulate the finger was made of nylon, a synthetic polymer.

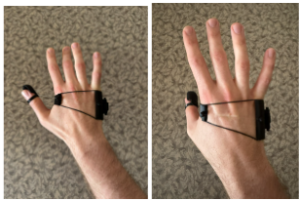

Overall, the first functional prototype allows for the independent usage of other fingers. The tension in the fishing line rotates and bends the finger. The relatively comfortable design does not harm the user. Figure 13 below displays a user in the palm up resting state, palm up active state, palm down resting state, and palm down active state.

Figure 13: First functional prototype in four states. (a) Upper left. User in palm up resting state. (b) Upper right. User in palm up active state. (c) Lower left. User in palm down resting state. (d) Lower right. User in palm down active state.

Although not perfect, this first functional prototype unlocks new abilities that were not present for users before. The four fingers can be utilized independently of the prosthetic and the thumb, allowing for greater utility and versatility. For example, simple objects such as raquet balls, Tic Tac containers, and other objects can be picked up without the use of the other four fingers. Other actions such as flexing filament cutters with the thumb and the prosthetic is more accurate and comfortable than flexing filament cutters with only a thumb and another finger. Additionally, compared to the PrimeCare Prosthetic cost being from $2,000 to $20,000, this initial prototype cost around $1.50. Although the cost will rise after notable improvements, the final cost is expected to stay around $10. Customizability is also something that is extremely easy to incorporate into the design without increasing the cost by a significant proportion. Finally, the passive characteristic of this prosthetic especially reduces the cost and reduces energy consumption. Overall, there are many opportunities for effective body augmentation in this project after improving the design. These all contribute to a high potential problem that exists in the prosthetic field.

There are a few downfalls of the first functional prototype that can be addressed for future functional prototypes. The first main downfall is that the grip strength of the prosthetic finger is highly dependent on the fishing line weight. After flexion, there is no mechanism to extend the finger again to set up for another flex. The introduction of a torsional spring to pull the finger back for another flexion would solve this issue. Next, the fishing line is in contact with the back of the hand and loses tension during use. A simple solution to this problem includes a longer guide or high guide on the hand grips to offset the fishing line from the back of the hand. Since this was an initial prototype, the goal of the fishing line was to determine if the mechanism worked as designed. Next steps would include designing a way the tension in the line stays constant throughout use. Finally, there is still movement by the hand grips on the user’s hand. This slight adjustment during use affects the functionality of the finger. Therefore, the hand grips can be modified to include a foam insertion to hold it stable to the outside of the hand, reducing this movement, and keeping the rotation of the finger constant.

Future Directions

There are many various future directions this project could take. These include tests to enhance grip ability, improving joint mechanisms, improving comfortability, optimizing cost, or replacing appendages. First, to enhance grip strength and grip ability, factors such as a rubber coating or alternate print materials could be tested on the prosthetic finger. TPU does not easily grip onto certain materials. Also, the joint mechanism currently in use for the prosthetic finger only uses the properties of TPU. The prosthetic finger’s joints can be further modified to match the movement of a natural human finger more closely. Next, as discussed before, the dimensions of the hand grips can be modified to increase comfortability for the user. Finally, the two main objectives, optimizing cost and replacing appendages, can be further pursued. FEA analysis can be conducted to determine where material can be removed to further decrease the cost of the entire prosthetic, making it more accessible. In addition, more research is needed to modify the current sixth finger prosthetic to replace a lost appendage for people with disabilities.

Conclusions

This project highlights the ease of prototyping that 3D printing presents, while also allowing a complex, multifaceted problem to be solved. Leveraging SolidWorks and a Bambu Lab X1 Carbon 3D printer, ideas became reality. The sixth finger prosthetic prototype that was made represents a small step that was made in the world of affordable, custom prosthetic devices. Previous designs allowed this project to have a good springboard to start and clever engineering allowed it to achieve its goal. The design overall encompassed that it is possible to design a functional device such as this to bridge the gap between technical, active prosthetics and passive prosthetics. The beauty of this device is that it could be customized to work for both a person missing a finger or as an additional appendage for those having all fingers. Much could be done to improve this prototype, such as the addition of a tensioning mechanism when a person’s thumb is in its resting position. Additionally, this device could function off of other joint movements to make it more natural than it currently is. Overall, this exercise pushed the boundaries of human modification to add functionality to a hand.

Acknowledgements

Professor Xiao Kuang

University of Wisconsin-Madison Design and Innovation Lab at Wendt

References

- Prosthetic Partial Hand & Fingers in Las Cruces & Albuquerque | PrimeCare. https://primecareprosthetics.com/prosthetics/prosthetic-hand-partial-hand-fingers (accessed 2025-05-07).

- J. Davenport, Materials Transformation Center, personal communication.

- M.A. Spalding, G.A. Campbell, F. Carlson, and K. Nazrisdoust, SPE-ANTEC Tech. Papers, 52, 792 (2006).

- C.I. Chung and R.A. Barr, U.S. Patent 4,405,239 (1983).

- S.A. Somers, M.A. Spalding, J. Dooley, and K.S. Hyun, SPE-ANTEC Tech. Papers, 41, 222 (1995).

- Dani Clode’s (MA Design Products, 2017) ‘Third Thumb’ design shows how the brain adapts to robotic augmentation. RCA Website. https://www.rca.ac.uk/news-and-events/news/dani-clode-ma-design-products-2017-is-using-her-third-thumb-design-to-show-how-the-brain-adapts-to-robotic-augmentation/ (accessed 2025-05-07).

- The Third Thumb. Dani Clode Design. https://www.daniclodedesign.com/thethirdthumb (accessed 2025-05-07).

- Lego Technic Axles | 3D CAD Model Library | GrabCAD. https://grabcad.com/library/lego-technic-axles-1 (accessed 2025-05-07).

- Thingiverse.com. Thumb Guard by clbwright. Thingiverse. https://www.thingiverse.com/thing:876863 (accessed 2025-05-07).