Apple AirPods Pro ULTRA

Saeed B, Griffin Z, Kade W, Shengyuan Z.

ME 514 Polymer Additive Manufacturing, Spring 2024.

Abstract

This project is focused on the design and fabrication of a personalized sleeve for Apple AirPod Pros, aimed at improving comfort and fit by aligning closely with the unique contours of the user’s ear. Given the widespread popularity of AirPods across diverse user demographics, it is challenging to achieve a one-size-fits-all design that accommodates the varied ear shapes of all users. Furthermore, standard AirPods often become loose or dislodge during physical activities such as running or exercising. This project addresses these issues by developing a product that functions as an adaptive accessory for AirPods, attaching directly to the device. The sleeve is tailored to individual ear contours and produced using additive manufacturing techniques. The project employs two primary additive manufacturing methods: Fused Deposition Modeling (FDM) and Stereolithography (SLA), along with an indirect manufacturing approach through silicone molding. This report evaluates the comparative effectiveness of these techniques in terms of comfort, stability, and sound isolation. Experimental results indicate that sleeves fabricated using SLA and silicone molding exhibit comparable performance, particularly in aspects of stability and sound isolation.

Introduction

Mass-produced items like AirPods typically employ a standard design and are produced using injection molding techniques. While it may seem efficient to utilize high-speed production processes like injection molding for manufacturing such devices, this approach often results in user dissatisfaction due to the one-size-fits-all nature of the products. Human ear dimensions are variable, with considerable differences in size and shape across individuals. Therefore, the universal model of products like AirPods can lead to issues, such as the earbuds dislodging during everyday activities such as running or walking. Addressing this clear gap necessitates a move towards customization, a key advantage of polymer additive manufacturing.

This project aims to leverage additive manufacturing to develop an auxiliary product that effectively addresses these shortcomings. The primary objective is to create a customized sleeve for AirPods that enhances comfort and ensures a better fit tailored to the user’s ear. The sleeve design should ensure that the AirPods are held securely in place yet can be removed easily without excessive force. As the sleeve will be in direct contact with the skin, selected materials must not cause discomfort or irritation. To achieve these objectives, it is necessary to select a 3D printing technology that supports flexible materials and delivers superior surface finishes and precise dimensional accuracy. Furthermore, performance testing must be conducted to evaluate the stability and sound isolation capabilities of the developed solutions, ensuring that the sleeves meet the desired specifications and user needs.

Methodology

Before 3D printing, 3D scanning was used to obtain a model of the ear’s internal shape. Since the product requires an accurate model of the inside of the ear, modeling directly with CAD software will result in deviations between the model geometry and the actual shape. Therefore, 3D scanning is the most effective method for recreating the inner ear geometry. For 3D printing, this project used two different technologies, FDM and SLA. FDM was used to print the preliminary design and concept model of the product, and SLA was used to make the final product. Both SLA and FDM can use flexible materials, but there are many differences in the surface quality and overall characteristics of the products printed by the two technologies, which will be mentioned in the following sections. Finally, silicone molding was also used to make the same product. The molds were made by 3D printing, but the AirPods sleeves were obtained by injecting liquid silicone into the mold. The product of silicone molding was compared with the 3D printed products when evaluating the design criteria.

3D Scanning

To ensure an accurate model of the internal structure of the ear, 3D scanning was the most straightforward solution. However, 3D scanning still cannot scan inside the ear directly, due to the poor lighting conditions. The approach used was to insert a wax plug into the ear, allow it to conform to the ear shape, then remove and scan the plug. Additionally, the physical AirPod was placed into the wax plug to create a scan that captured the entire silhouette of the product. The equipment used for 3D scanning was the Creaform Handyscan 700. Before scanning, the object is placed on a rotary table lined with reflective markers. During scanning, the table is rotated to capture the object from all directions. Since part of the object resting on the table is not visible to the scanner, the scan was divided into two parts. First, the upper half of the object was scanned, then the object was flipped, and the lower half was scanned. Finally, the two parts were merged using a mesh processing software, called Mesh Mixer.

Fused Deposition Modeling (FDM)

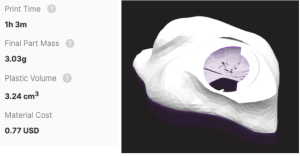

For the initial printing trial, Fused Deposition Modeling (FDM) was used to fabricate the sleeve. A dimensionally accurate 3D model of an AirPod was sourced online and integrated into a 3D modeling software (Blender), alongside the scanned ear model. The two models were overlaid to simulate the placement of the AirPod within the sleeve, and the overlapping volume shared between them was subtracted from the ear model to create a cavity. This modified model was then printed, as depicted in Figure 1. The total print time was just over an hour and only cost 77 cents. The print was oriented with the outer face down to minimize support material on surfaces that will be inserted into the ear. Given the emphasis on maximizing user comfort in the design, Thermoplastic Polyurethane (TPU) was selected for printing due to its flexible properties.

Figure 1. Print settings and model for FDM trial.

FDM was mainly used for the first print due to the speed of the process. As this trial was very early in the project, it was important to the team to get immediate results that could be used to consider what parts of the design are satisfactory and what may still need to be improved. FDM is also quite cheap, making it a good option for a rough prototype.

Stereolithography (SLA)

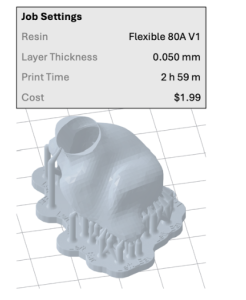

The second additive manufacturing method used to create the AirPods sleeve was Stereolithography (SLA). SLA involves using an ultraviolet (UV) laser to selectively cure and solidify a liquid resin contained in a vat. The team decided to pursue this method as it provided several advantages over FDM and would hopefully overcome the problems experienced in the initial print. First, SLA parts have a high-quality surface finish and layer lines are far less visible. Second, SLA printers have a much wider variety of available materials with different material properties, such as flexible and elastic resins. Finally, SLA provides a high degree of resolution and print accuracy, meaning it can achieve fine details in the final part geometry. The sleeve was printed on the Formlabs Form 3 printer, using Flexible 80A V1 resin. The print settings are described in Figure 2.

Figure 2. Print Job settings for part made via SLA.

The print orientation was selected so that no support structures attach to the surface in contact with the ear. The shortest layer thickness of 50 micron was used, to enhance details and to improve surface quality. The part took about three hours to print, one hour of post processing to remove support structures, and cost about two dollars.

Indirect Molding – Silicone

The final method used to create the AirPod sleeve was a subset of additive manufacturing, known as indirect prototyping. In this approach, rather than printing the part directly, 3D printing is used to create a part mold, and then an alternative method is used to cast or mold the final part. For this project, the method used was silicone molding. In silicone molding, two parts of liquid silicone are mixed in equal volumes, poured into a mold, and allowed to cure and solidify. Additive manufacturing was still necessary to create the part mold. The team decided to print the mold using SLA to ensure that the mold would be highly accurate and that the mold surface would be smooth and free of layer lines.

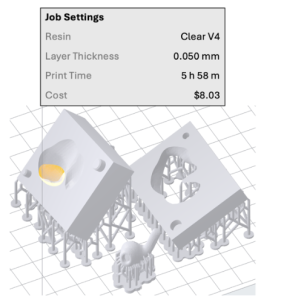

The mold was printed on the Formlabs Form 3 printer, using Clear V4 resin. The print settings are described in Figure 3.

Figure 3. Print Job settings for part mold made via SLA.

The Clear V4 resin is transparent and was selected so that the mold filling process could be observed. The print orientation was selected so that minimal support structures attach to the mold surface or to the mold parting line. The mold took about six hours to print, one hour to post process, and cost about eight dollars. The two halves of the mold were assembled, and the SLA AirPod was set in place to create the hollow cavity for the real AirPod. Finally, a liquid silicone compound called Dragon Skin 30 was mixed, poured into the mold, and allowed to cure for 16 hours.

Results and Discussion

3D Scanning

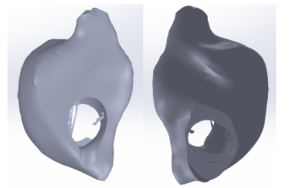

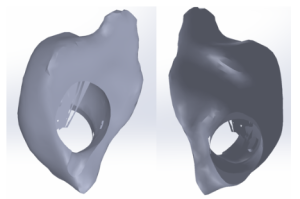

Figure 4 presents the initial 3D scanning result that was utilized for FDM printing. Some irregularities within the cavity were caused by environmental interference during the scanning process; however, these can be automatically corrected during post processing of the mesh. Figure 5 displays the final 3D scanning result, which was used for SLA printing. Compared to the initial scan, the hole has been enlarged to ensure that the AirPods can be easily inserted.

Figure 4. Initial 3D scanning

Figure 5. Final 3D scanning

Fused Deposition Modeling (FDM)

The result of our first print trial is shown in Figure 6 below.

Figure 6. FDM printed TPU 92A sleeve

Testing this sleeve showed that it did fit snugly in the ear. This provided evidence that the primary tenets behind the design were sound enough for the team to continue with this project, though there were still several issues with this initial design that needed to be addressed in future trials. While the sleeve fit into the ear, the AirPod itself did not fit into the hole of the sleeve. This was likely because adequate tolerances were not included in the print to account for shrinkage or other printing imperfections. Scaling the size of the hole in future models to account for this was a revision made for subsequent trials.

Along with the geometry of the sleeve, its physical properties had several issues that needed to be addressed as well. While TPU is more flexible than other plastics compatible with FDM, it was still fairly stiff, and was not comfortable when placed in the ear for extended periods of time. The speed of FDM also meant the print’s surface finish was low, as indicated by the visible layer lines on Figure 6. This low-quality finish not just looks unappealing but feels rough and uncomfortable in the ear as well. Using higher quality printers and more flexible materials was a design decision that the team all agreed upon for future trials.

Stereolithography (SLA)

The result of the second print trial is shown in Figure 7 below.

Figure 7. Sleeve made of Flexible 80A resin (top). Sleeve with AirPod inserted (bottom).

The second print trial yielded several positive outcomes. The AirPod inserted into the sleeve with relative ease and fit securely. The part had excellent surface quality, with no visible layer lines, enhancing its aesthetic appeal. Additionally, Flexible 80A resin is translucent, so the sleeve remains somewhat discreet when worn in the ear. Despite these successes, there were areas requiring improvement. The fit of the AirPod was too snug and required moderate force for removal, which poses a potential risk of damage to the device. Although the Flexible 80A resin provided flexibility, the thick-walled sections of the sleeve still felt hard and plastic-like, compromising comfort. Lastly, the SLA process necessitates the use of support structures, which left visual defects on the exterior surface of the sleeve where these supports were attached.

Indirect Molding – Silicone

The part that resulted from the silicone molding method is shown in Figure 8.

Figure 8. Sleeve made of Dragon Skin 30 silicone (top). Sleeve with the AirPod inserted (bottom).

The final trial produced overwhelmingly positive results and improved upon the issues identified in earlier direct manufacturing methods. The AirPod could be easily inserted and removed from the sleeve, while the elastic properties of silicone ensured a secure fit. Additionally, the softness of the silicone enhanced the comfort of the sleeve, making it barely noticeable in the ear even after prolonged use. The surface quality of the silicone part was notably superior, benefiting from the absence of support structures. A further qualitative assessment of each of the three previous trials was also carried out during validation testing.

Pulling Force

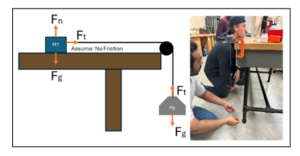

To assess the stability of the proposed solutions involving 3D-printed sleeve by SLA and an indirect manufacturing approach, a simple pully system was designed as shown in Figure 9.

Figure 9. Stability Testing

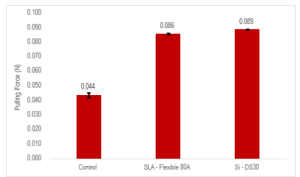

A thin rope was tightly secured around the AirPod, AirPod with 3D-printed sleeve prepared by SLA, and AirPod with silicon sleeve prepared by indirect manufacturing. Incremental mass, denoted as m2, was gradually added to the opposite end of the rope. As the weight increased, reaching a critical point, both sleeved and unsleeved AirPods were dislodged from the ear canal. Figure 10 shows the improved stability of the suggested sleeve solutions within the ear.

Figure 10. Pulling Force.

Sound Insulation

To evaluate the sound insulation effects of the different sleeve materials, including Formlabs Flexible 80A V1 resin and silicone, a simple experiment was conducted using an electronic sound source. Sound levels were recorded at six meters from a person wearing AirPods, both with and without proposed sleeves. As shown in Table 1, the addition of sleeves did not provide any sound isolation benefits when compared to AirPods without sleeves.

Table 1. Recorded Sound Levels (dB).

| Configuration | Distance to Sound Source (m) | Sound Level (dB) |

| Control | 6 | 48 |

| SLA – Flexible 80A V1 | 6 | 51 |

| Silicone – DS30 | 6 | 50 |

Conclusions and Outlook

This project was carried out with the goal of creating a custom-made sleeve for Apple AirPods that increased their stability and comfort during use. Three different manufacturing trials were performed, and the properties of each resulting sleeve were tested and compared to each other to conclude which design best fulfilled the project’s goals.

The first trial utilized FDM to print the sleeve with TPU. This first design showed that the sleeve could fit in the ear, but it was still quite stiff and the AirPod could not fit into the sleeve. For the second trial, Stereolithography (SLA) was used to print the sleeve out of 80A V1 resin. This process resulted in a much more comfortable and flexible sleeve that the AirPod could fit into, though some parts were still fairly stiff and the support structures from the print warped some of the geometry of the sleeve. Finally, for the third trial, a printed mold was used to cure a sleeve made from a silicone compound called Dragon Skin 30. This final design was an across-the-board improvement over the previous two trials, being flexible, secure, and comfortable. Through testing, it was found that both the SLA and Silicone designs were able to stay secure within the ear at over twice the amount of force when compared to regular AirPods.

Utilizing additive manufacturing processes to create a custom AirPod sleeve resulted in a design that made daily use not just more secure, but more comfortable as well. If this project were to be continued, other types of silicone could be tested to see if the sleeve can be made more comfortable and visually appealing. Improvements to the workflow could also be made to increase the rate at which the sleeves can be manufactured.

References

“Apple AirPods pro 3D Model | 3D Model.” CGTrader, www.cgtrader.com/3d-models/electronics/audio/airpods-pro-3dmodel.

“DIY Apple AirPods to Your Custom Earphone.” www.uniz.com/us_en/blog/post/diy-apple-airpods-to-your-custom-earphone/.

“3D Scanners.” UW Makerspace.

https://making.engr.wisc.edu/3d-scanners/

“3D Printers.” UW Makerspace.