Brief Explanation:

Plants are mostly either planted in cheap thermoformed plastic pots or heavy and expensive ceramic pots. 3D printing offers the potential for a middle ground between these two, something that is strong but light, and aesthetically pleasing with the opportunity for more advanced structures not feasible with thermoforming or pottery. As a demonstration of this, we are planning to make a succulent pot waterwheel, which will allow for even and thorough watering of several small succulent plants and have a visually appealing design.

Preliminary Designs:

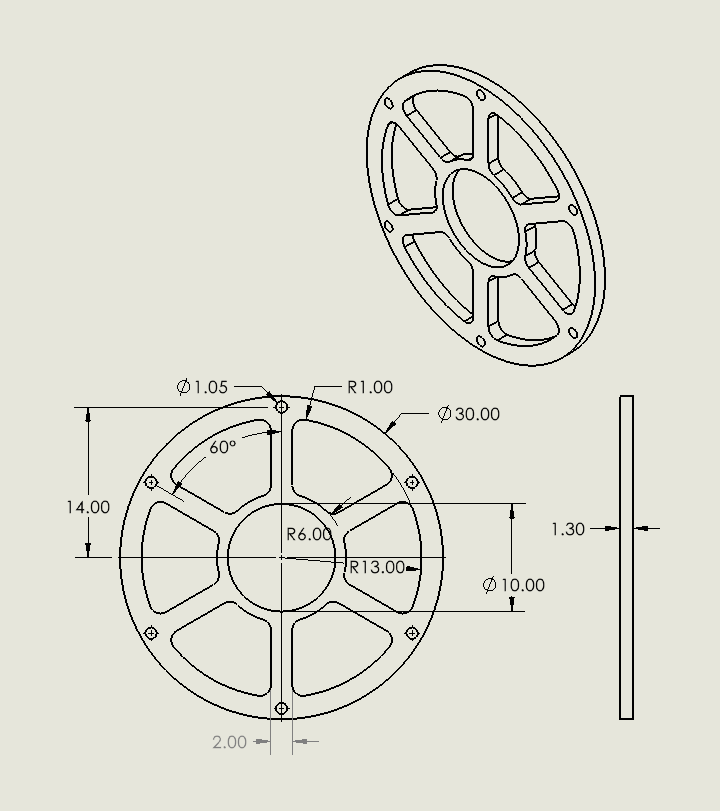

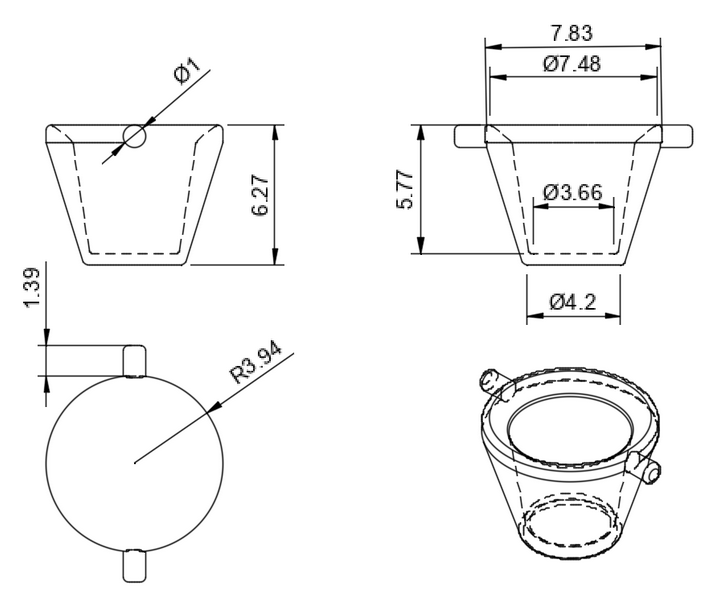

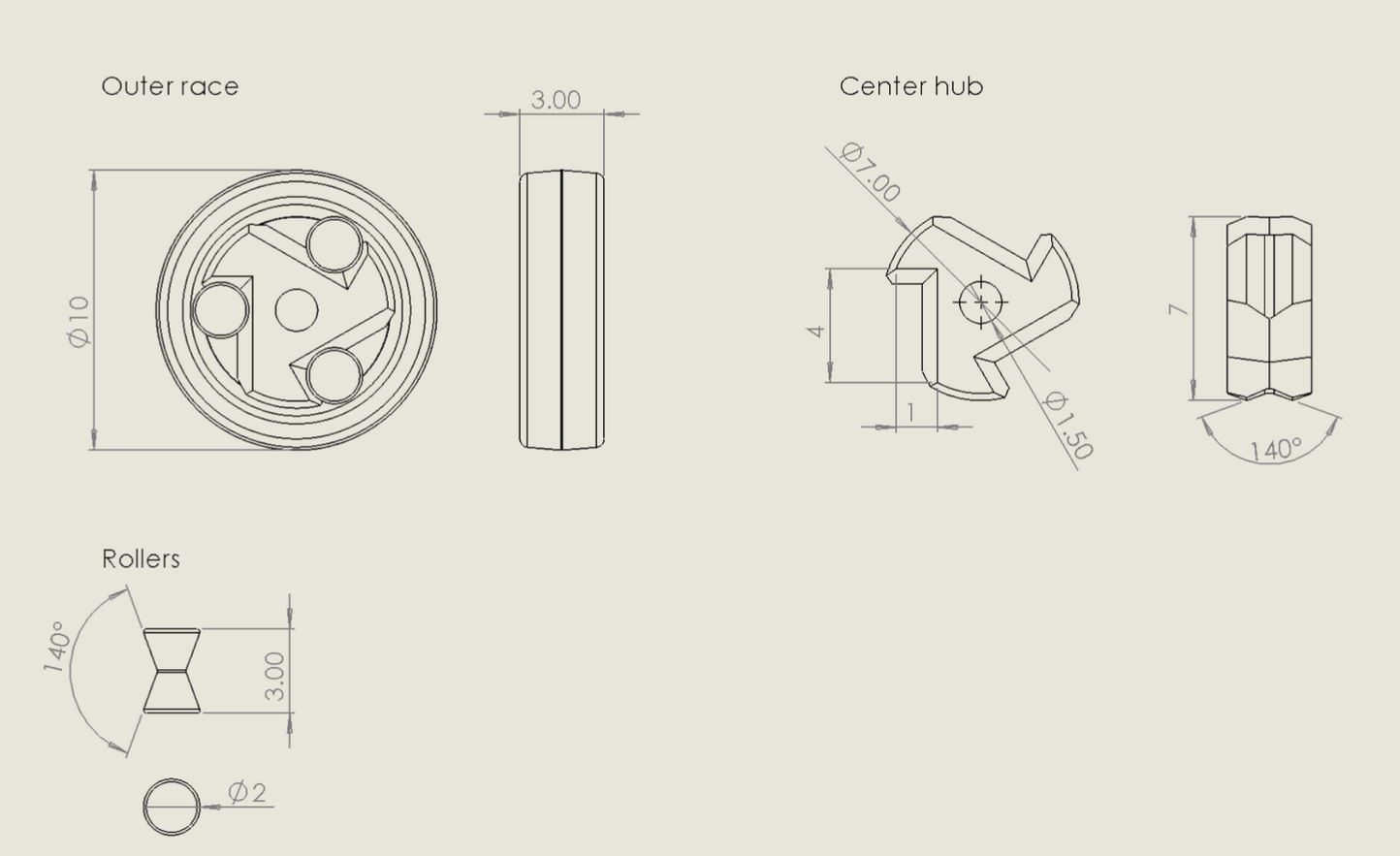

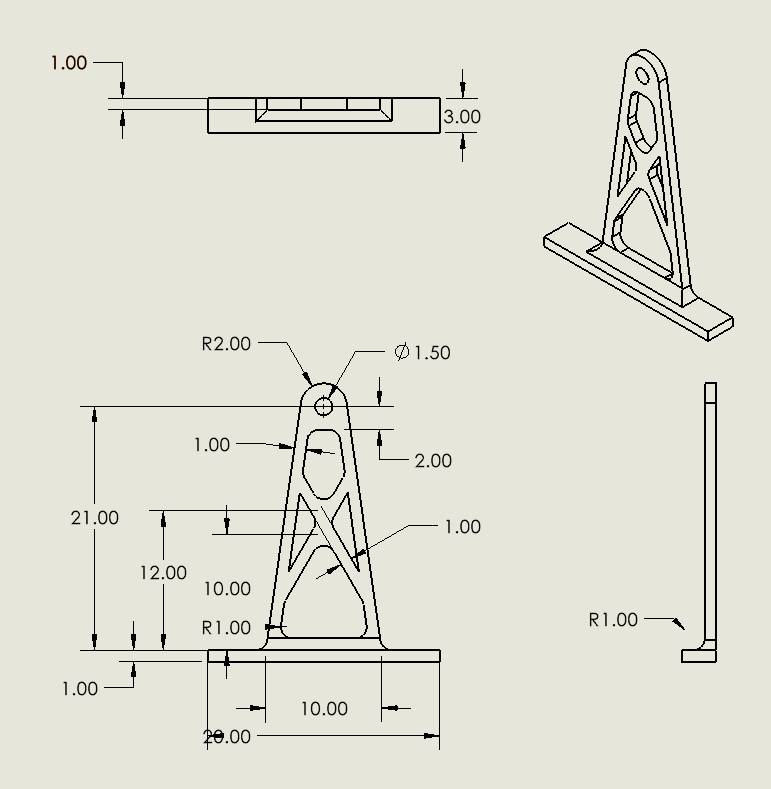

The assembly will be built similarly to a Ferris wheel (ref to Fig 1.) consisting of two parallel wheels with a diameter of ~30 cm mounted about 6 cm apart from each other on a common axle and a base that gives them enough clearance to spin freely. The wheels will rotate on a one-way bearing. There will be six pots suspended from these wheels, spaced evenly around the circumference. The pots will have a traditional flower pot shape (ref to Fig 2). There will be two pins opposite each other on the top rim, which will sit in a hole in each wheel so that their position is fixed but their rotation is freed. Also these parts have adequate fillet radius to make the edge smooth and user friendly.

Fig. 1: Wheel for pots to sit in, unit in cm

Fig. 2: Pot design, units in cm

Fig. 3: One way clutch assembly, units in cm

Fig. 4: One of the supporting legs, units in cm.

Manufacturing Considerations:

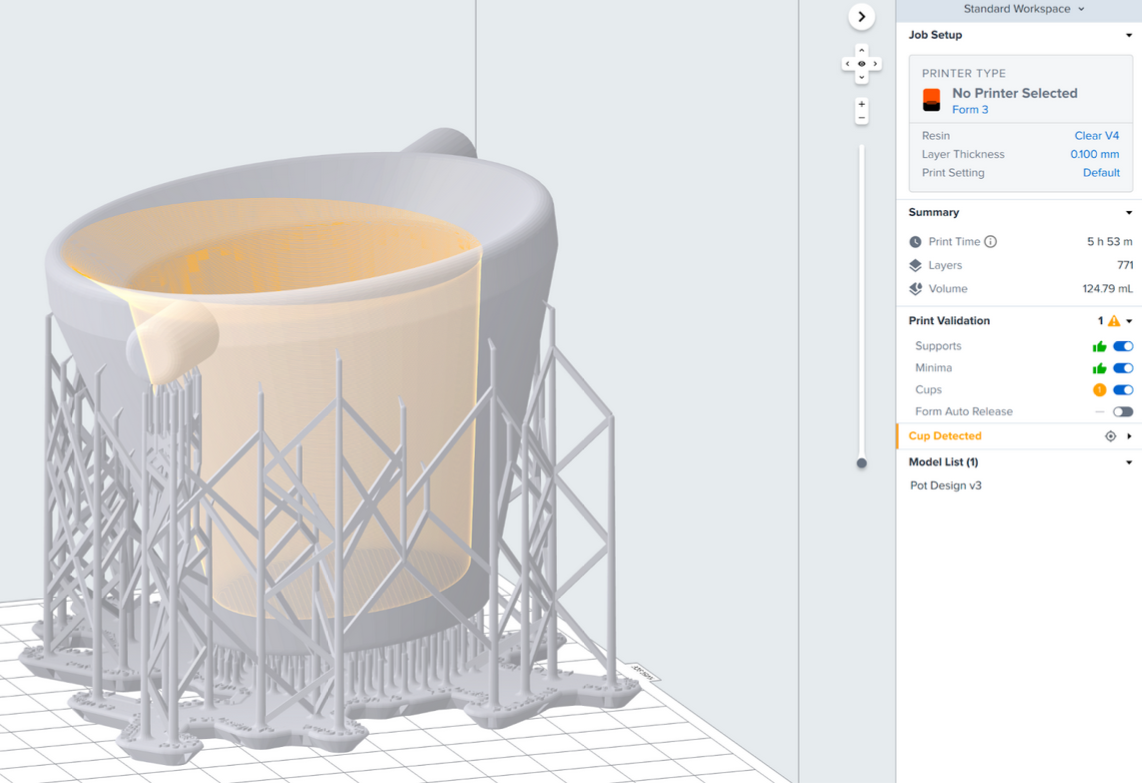

The pots themselves have more requirements for their physical properties than the rest of the structure. We chose SLA as the method of printing for these with clear resin , to make sure that water can not get into the walls of the pot. To avoid this issue with FFF, we would either have to make the layer height much smaller than otherwise necessary due to the other design considerations, or use a post-processing technique such as vapor smoothing. We plan on using Formlabs Clear Resin. For the wheel and its base, we plan on using FFF printed white PLA, because we do not expect the conditions it experiences to be very demanding, and therefore printing speed and cost takes priority.

Proposed First Print and Experiments:

The goal of the first trial will be to verify the structure can be assembled, spin freely, and hold weight. For now, the bearing will be attached to the wheel with adhesive. In the future, we will either merge the two pieces or design them to fit together without adhesive. Our first test, after assembling the design, will be to fill each of the pots most of the way with water and manually turn the wheel. The wheel should spin freely around its axis, and the pins holding up the pots should be able to freely rotate in their housings, so that the pots always remain upright. The water in the pots will act as ballast to simulate the weight of the soil and plant. Our goal is ten consecutive revolutions without incident. We will use the results of this test to evaluate our tolerances and the design of the wheel.

Fig. 5: PreForm sliced part, it takes 6 hours per pot