Background:

Riding on a tire with low air pressure can lead to damage to the tire, inner tube, and rim. If the tire is flat, there’s a risk of it dislodging from the rim, potentially resulting in a crash. Airless tires are designed to mitigate the need for riders to address punctures, reducing the associated risk and allowing drivers to feel safe while driving on the road. Without the need of air in tires, this eliminates the necessity for pressure checks, making it ideal for self-driving vehicles. Additionally, 3D printed tires will reduce the environmental footprint by reducing scraps and energy used in tire production.

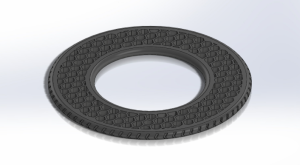

Our goal for this project is to design and 3D print an airless bicycle tire.

Preliminary Designs And Manufacturing Considerations:

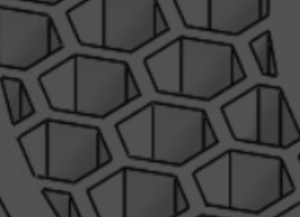

The interconnecting hexagonal shape of a honeycomb structure allows for low-density with high-strength characteristics for numerous different engineering applications, ranging from nanoscale to macroscale[1]. The shape memory of a honeycomb structure allows the ability to restore from the temporary shape to their memorized permanent geometry after receiving a physical change[2]. Due to its numerous advantages, our preliminary design of the airless tire will consist of a honeycomb-like construction surrounding the tire. Additionally, thread patterns with low thread depths will be printed along the outer surface of the tire to provide additional grip between the tire and the road.

The additive manufacturing process chosen for the printing of the tire is fused deposition modeling (FDM). The benefits associated with an FDM printer encompass cost-effectiveness and rapid printing capabilities. Thermoplastic polyurethane (TPU) is characterized by its high elasticity and resistance to abrasion, making it an ideal material to print an airless tire [3].

Proposed First Print Trial, Experiments or Similar:

The project intends to utilize the Stratasys F370 printer that is available at the UW Makerspace to fabricate the airless tire. Filament that will be used to print is FDM TPU 92A [4] [5].

Given the standard road bike tire dimensions of 700mm in diameter and 23mm in width, adjustments are necessary due to the Stratasys F370’s maximum build size of 355mm x 254mm x 355mm. Consequently, for the initial test prints, the project will scale down the dimensions by a factor of 4, resulting in a print size of 175mm in diameter and 5.75mm in width.

It’s anticipated that the printed parts will feature supports situated within the inner walls of the tires, along with thread patterns. Thus, subsequent post-processing steps to eliminate these supports will be necessary prior to conducting any functional testing on the printed tire.

References:

- Huang, J., Zhang, Q., Scarpa, F., Liu, Y., & Leng, J. (2017). Shape memory polymer-based hybrid honeycomb structures with zero Poisson’s ratio and variable stiffness. Composite Structures, 179, 437–443. https://doi.org/10.1016/j.compstruct.2017.07.091

- Mishra, R., Jiri Militky, & Venkataraman, M. (2019). Nanoporous materials. Elsevier EBooks, 311–353. https://doi.org/10.1016/b978-0-08-102609-0.00007-9

- Thermoplastic Polyurethane (TPU) Material: Properties & Structure. (2024). Specialchem.com. https://omnexus.specialchem.com/selection-guide/thermoplastic-polyurethanes-tpu#:~:text=A%20drawback%20is%20that%20they,%2C%20are%20inherently%20light%2Dstable

- F123 Series – FDM 3D Printer. (2024). Stratasys.com. https://www.stratasys.com/en/3d-printers/printer-catalog/fdm-printers/f123-series-printers/

- FDM TPU 92A: Flexible Elastomer TPU 3D Printing Material. (2024). Stratasys.com. https://www.stratasys.com/en/materials/materials-catalog/fdm-materials/tpu-92a/