Project Overview

The goal of our project is to produce part of the steering wheel for the Badgerloop team. Badgerloop is the solar car team at the University of Wisconsin – Madison. The team competes in the American Solar Challenge (ASC). The steering wheel will be part of the first car the team has ever built. The steering wheel design has multiple components: the front and back plates, the body, the buttons, the screen, and the fasteners. The only component that will be manufactured for this project is the body. The body consists of handles that are connected by two connecting bars. These components are a singular solid body that will be printed at once. A CAD model of the part is shown in figure 1 below.

Figure 1: A screenshot of the CAD model of the steering wheel assembly.

Project Update

Since our project proposal, we have made progress in determining both the initial manufacturing process and material. After weighing many options, we came to the conclusion that the Fused Form 600 printer is the best option to proceed with. The main reason we chose this individual printer is because of the overall size of the print. The steering wheel that we are creating is roughly 13” x 13”, which eliminates many of the printers available to us in the laboratory. This printer has a large enough bed for us to print the part in one piece. Our initial design choice for the material was PLA because of its availability in the lab and its stiffness.

Analysis

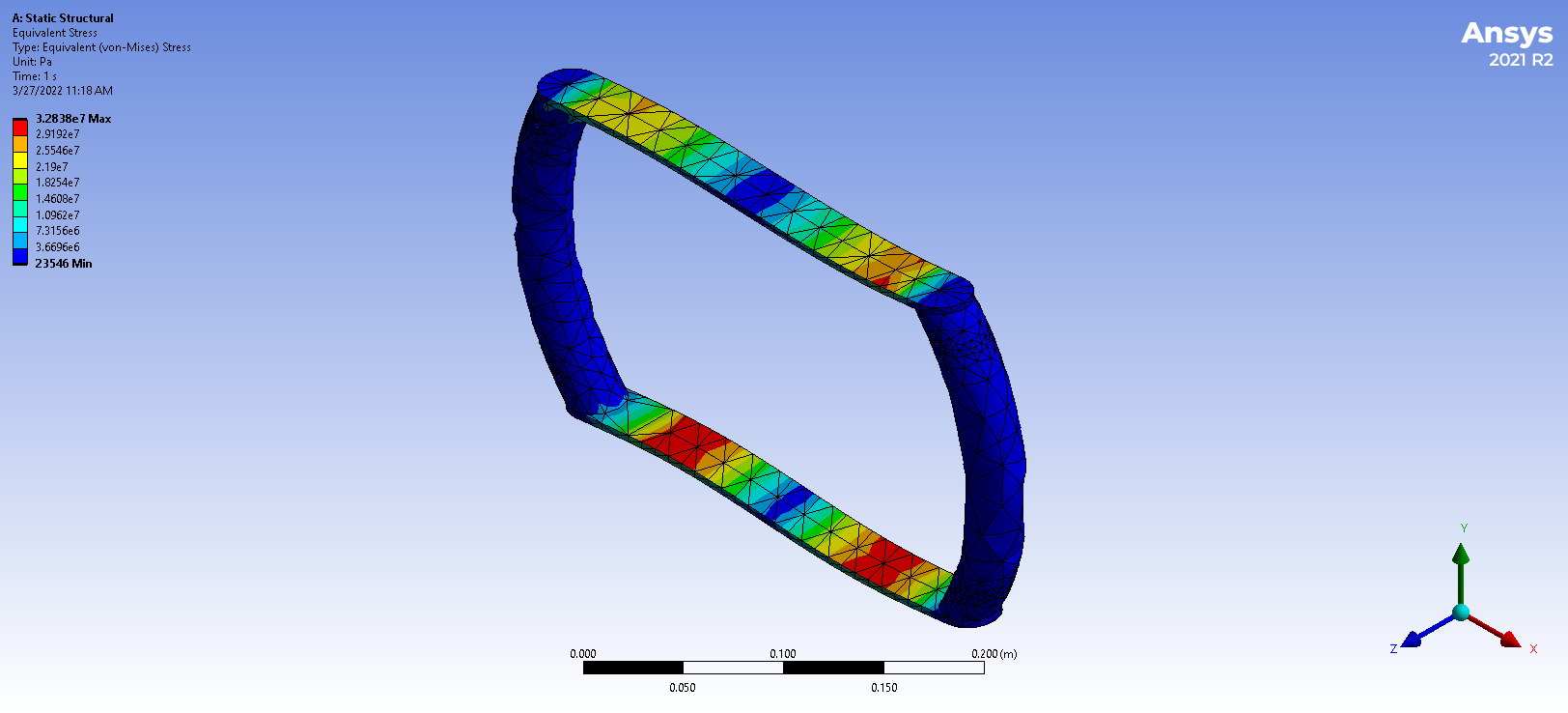

Due to some of the performance requirements of the steering wheel and the amount of material needed to produce the part, we believed that it was best to run analytical testing before printing a physical model. We decided that this would help us improve upon our chosen manufacturing process and material choice without wasting a large amount of material. The initial analysis conducted on the steering wheel was done in Ansys. The method for these tests was fairly simple. Using information from a National Highway Traffic Safety Administration report we determined the maximum amount of force that would be put on the wheel. We then loaded the wheel model into Ansys and pinned the wheel at the center. This meant that the wheel would not rotate when the forces are applied so we would get a true measurement based on the applied torque. A force of 145 Newtons was applied to each of the handles, one going up, the other going down, as if the wheel were being used. The results of the first test can be seen in Figure 2.

Figure 2: Results of the first stress test in Ansys

The first test showed that the max stress occurred in the top and bottom bars that connect the handles. This max stress was around 33 MPa which was a little close to the tensile strength of the polymers we were considering. This led us to thicken the top and bottom bars and run a second test. The results of the second test are shown in Figure 3.

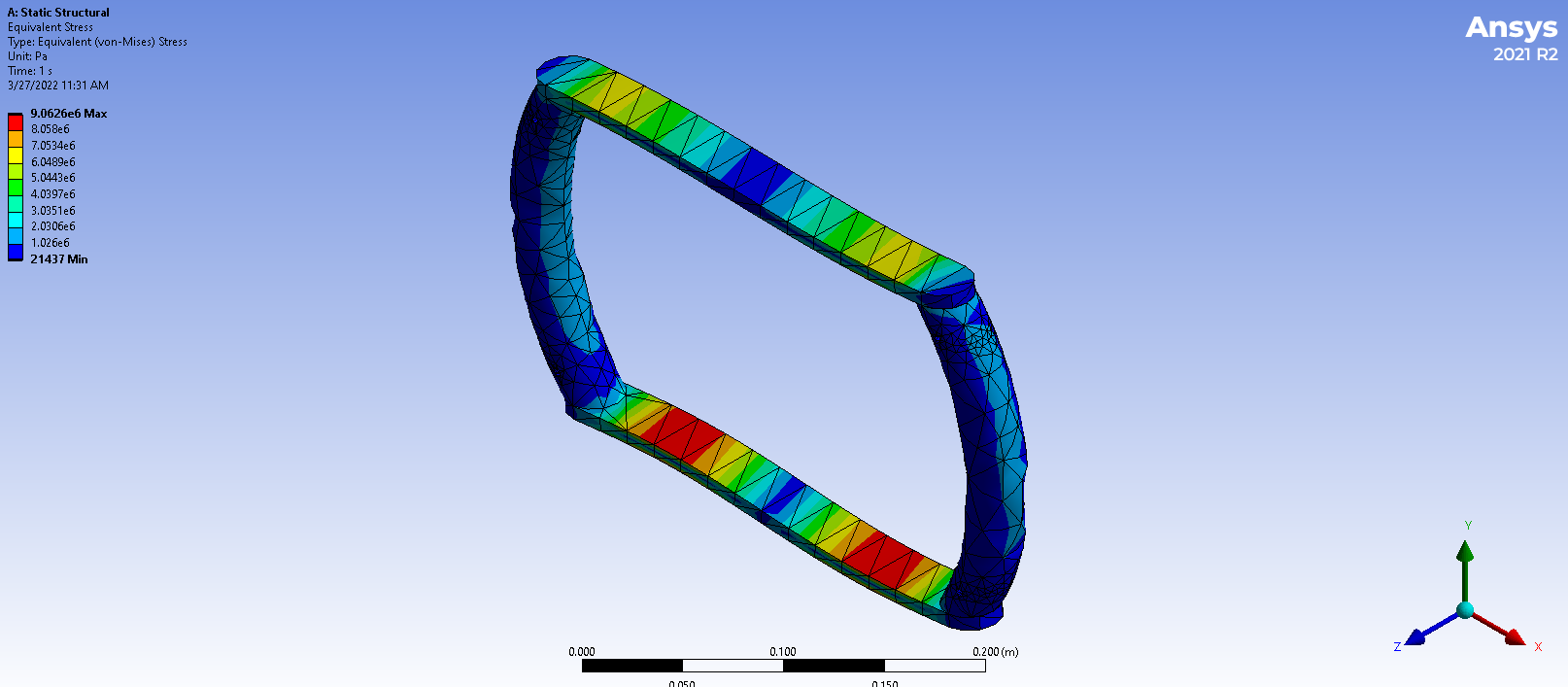

Figure 3: Results of the second stress test in Ansys

As expected the maximum stress still appears in the same locations; however, this stress was much more manageable as it was estimated at around 9 MPa.

After analysis, we concluded that PLA was not the best direction for our project to follow. This is because of the thermal and torsional stresses being put on the steering wheel. The steering wheel needs to sustain push, pull, and torsion tests up to 100° Fahrenheit. PLA has poor heat resistance properties, which makes it unreliable in our application. Because of the thermal property requirements of our steering wheel, we considered changing our material to a thermoset such as an epoxy. Thermosets have higher heat resistance due to the curing process that they undergo during additive manufacturing. However, it is unlikely that we would be able to use this type of material in an application this large. After eliminating thermosets, more thermoplastics were identified as possible materials. The two best options remaining to us were ABS and polyamide. The ABS that we identified is readily available in the lab. ABS is more heat resistant and durable than PLA. It is also more affordable than the Polyamide we identified. However, the Polyamide is infused with carbon fiber, which increases the stiffness of the print and also undergoes very insignificant warping during the printing process. Both of these materials are used by the Fused Form 600 printer that we initially planned on using.

After analysis, we decided to proceed with the ABS seeing as it is readily available and we will use the Fused Form 600 printer in the ME 514 lab as soon as possible. Once the print is completed, we will do push, pull, and torsion testing on the physical print and verify that this testing is consistent with the testing done in Ansys. If the ABS fails testing, we will consider doing a version in Polyamide next.