Background:

In the fishing industry, some of the most popular lures are hard plastic crankbaits and jerkbaits. Hard plastic lures are currently made from two injection molded halves that are fused together after weights and other features are added. In post processing, the lures are painted externally with designs that are prone to wearing off and give the appearance of being two dimensional. With additive manufacturing, the lure can have three dimensional features embedded into the part, removing the need for painting and making the lure more realistic to fish.

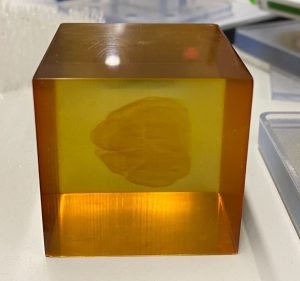

For this project, stereolithography (SLA) is the chosen additive manufacturing method for accomplishing three dimensional features inside the part. A transparent resin will be cured using SLA and, for the areas where a feature is desired, the UV light will pass over that location multiple times. Passing over the cured resin multiple times will change the shade of the resin. This process can be achieved by layering multiple parts over each other, which will prompt the printer to run UV light over a location several times. The darker shades will appear to be solid features inside the finished part.

Figure 1. Completed print using the overcuring process

Objectives:

- Test different resins for susceptibility to discoloration from overcuring

- Manufacturing small scale proof of concept

- Print fishing lure with desired internal features

Preliminary Designs and Manufacturing Considerations:

This project will utilize stereolithography as the additive manufacturing technique which will require computer models of our parts to be created. Each internal feature of the lure will need to be its own model and that way features we wish to accentuate can be printed multiple times to increase the color density resulting from the cure. Resins similar to Accura 60 will work well for this application.

Figure 2. Initial fishing lure design

Proposed first print trial, experiments, or similar:

For our initial print, we will design several parts that will combine into an assembly that can be printed all at once. We anticipate adding features such as gills and fins to the outer surface of the fishing lure and internal features such as a semi-transparent skeletal frame. Our first print will largely be intended to test the material we use and determine an appropriate print time. It will also be used to develop a model for how the shading within the part relates to the number of curing passes, since this is expected to be strongly correlated. As more information is gathered, it is anticipated that additional complexity may be possible for internal components, and ultimately result in a more appetizing design, at least from the perspective of the fish.