Project Overview

Framing a poster can be expensive and add a lot of weight to a poster. This excess weight can make large nails a necessity to hang up any posters in a dorm or apartment, which are far more difficult to repair due to the large hole, as well as the need for a hammer or other tools. Other solutions such as thumb tacks and adhesive putty can cause damage to the poster itself. For this reason we are looking to make a poster hanging system that will allow for a cheaper alternative to frames, while still not damaging the poster like a thumb tack would. Our initial concept is a device that attaches to the corners of posters while not damaging them, which has a tack sticking out of it to be attached to the wall.

Preliminary Design

Our preliminary design is a single print consisting of a corner triangle with a gap of .004 in (typical width of paper), a larger gap in the middle, and a tack on the back. The poster can be slipped into the gap without the corner catching and then secured to the wall with a tack. This will allow for the poster to be hung without damaging the poster. The size of the gap may need to be adjusted in order to provide enough clamping force to hold the weight of a poster. Soluble support structures are planned to be used in order to have a clean poster gap.

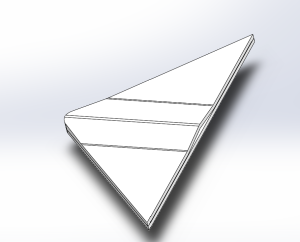

Figure 1: Isometric view of preliminary design.

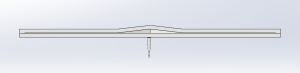

Figure 2: Front view of preliminary design.

Figure 3: Rear view of preliminary design.

Manufacturing Considerations

The additive manufacturing process that will be used for this design is fused filament fabrication (FFF). FFF is best suited for this project as it is one of the cheapest and fastest processes. Cost is a top priority as the target audience for this design is college students looking to hang posters on their walls. Faster prints will allow for less time between iterations and altogether cheaper manufacturing cost. A large part of this project will be experimenting with different methods of providing a clamping force onto the poster, so cheap and fast manufacturing is highly desirable for lowering research and development cost. A limitation of FFF is the ability to produce complex prints without excessive supports, but this design will ideally have simple enough geometry that this will not be an issue. The orientation of the part while being printed will have to be considered to assist in limiting the amount of support material needed. Less support material will allow for less material usage and less post processing time. FFF also does not produce as smooth of a surface finish as other processes, such as stereolithography (SLA), but surface quality is not a driving factor in this project. The UW-Madison Makerspace has over 30 Ultimaker FFF printers that could be used for this project [https://making.engr.wisc.edu/3d-printers/]. These printers have a resolution up to 20 microns, depending on the model of printer and nozzle being used [https://www.ultimaker.com/3d-printers/ultimaker-s5]. This resolution is more than satisfactory for our application.

The two materials we wish to test for our design are ABS (Acrylonitrile Butadiene Styrene) and PLA (polylactic acid). These materials are widely used for additive manufacturing applications. Various material properties of these materials are shown in Table 1.

Table 1: Material properties of PLA and ABS. Obtained from matweb.com.

| Material | PLA | ABS |

| Flexural Yield Strength [MPa] | 76.7 | 73.4 |

| Flexural Modulus [GPa] | 3.66 | 2.17 |

| Shrinkage [%] | 0.2-0.25 | 0.7-1.6 |

| Processing Temperature [C] | 173 | 162 |

| Heated Bed | Optional | Required |

| Price [$/gram] | 0.08 | 0.08 |

Since price is the main consideration of this project, and both materials are around $0.08 per gram, we must analyze other properties such as shrinkage and flexural yield strength to find the most suitable material for our application. Our design is quite compact so reducing the shrinkage in our print will be very important. We can see from Table 1 that PLA has significantly lower shrinkage compared to ABS, ranging from 0.2% to 0.25%. While Young’s Modulus may be a useful property to compare metals or ceramics, flexural modulus is more useful when comparing plastics. Flexural modulus is the property that is computed as the ratio of stress to strain in flexural deformation, or the tendency for a material to resist bending. This is more applicable for our purposes because our poster clamps will most likely fail due to excessive bending.

It is worth noting that PVA as a water soluble material will be used for a support structure while printing. It will likely be needed on the top side of the part, and inside where the poster goes. Some iteration may be necessary to reduce the amount of support needed.

Initial Work

The ability of the poster clamps to securely hold the posters in place without damaging the poster will be tested. This testing procedure will measure the movement of the clamped poster over the span of a week using a numeric scale. Once a design has been printed, three sets of the poster clamps will be printed. Three posters will then be hung up: one with no added weight and the other two with weight added through paper clips or binder clips. The added weight is to account for heavy material posters that the clamps would need to secure. The initial position of the posters in relation to their clamps will be marked and documented, and then the posters will be left for one week. After one week the position of the posters in relation to their clamps will once again be marked and documented. The initial and final positions will then be compared to quantify the clamping ability of the poster clamps. Any movement of the poster will signify that the clamps are not holding the poster rigidly enough. Each poster will also be checked for damage after being removed from the clamps. New designs will be made based on the results from this testing process. This testing process will be repeated for all designs and materials until satisfactory results are found.

Another factor that must be tested is ease of installation. While the poster clamps must hold onto the poster, they must also be easily secured to the wall. Ease of installation will be measured by the tools needed and the time taken to mount the clamp onto a wall.