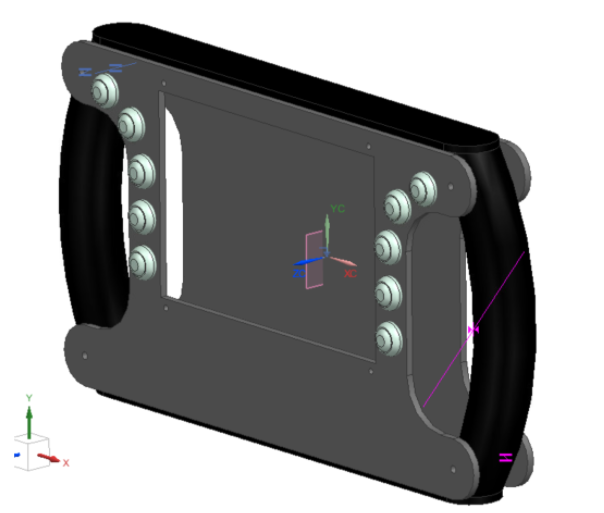

Figure 1: A screenshot of the CAD model of the steering wheel assembly.

Project Overview

The goal of our project is to produce part of the steering wheel for the Badgerloop team. Badgerloop is the solar car team at the University of Wisconsin – Madison. The team competes in the American Solar Challenge (ASC). The steering wheel will be part of the first car the team has ever built. The steering wheel design has multiple components: the front and back plates, the body, the buttons, the screen, and the fasteners. The only component that will be manufactured for this project is the body. The body consists of handles that are connected by two connecting bars. These components are a singular solid body that will be printed at the once.

Preliminary Designs

There has already been significant design work done on the steering wheel and the steering wheel body itself. A screenshot of a CAD model of the steering wheel assembly with the plates, buttons, and body is shown in Figure 1 above. The body is the black component of the assembly. These designs are subject to change depending on the needs of the Badgerloop team, the results of any analysis and testing performed, and any requirements for manufacturing.

Manufacturing Concerns

There are a few manufacturing concerns to take into account for this project. The steering wheel produced must be validated sufficiently so the ASC inspectors will allow the car to compete. This means the steering wheel body will be subject to sustained push, pull, and torsion tests under race day conditions. These tests will be designed by our team in conjunction with the Badgerloop team. With this in mind, special attention must be put towards determining the right material for the print as it must withstand these sustained forces. Additionally, the size of the body print will come into play. The diameter of the print will be a little over a foot, meaning that some of the available printers have a print bed that is too small for our part. This could limit the material selection and could vary the print time.

Trials and Experimentation

As mentioned in the manufacturing concerns section, this steering wheel must pass many validation tests. It also will most likely take a relatively large amount of material to produce. This means we will hopefully do enough analysis beforehand to only have to print the steering wheel one time to run our tests on and use the same print for the final product. Once printed, we will have to perform all the tests planned and make any changes required.