Team 8

Project Overview

Accessible maps for the visually impaired are designed to communicate the same or at least a sufficient subset of the information contained in a visual map. Accessible maps can use two channels of perception: hearing and tactile sense. Tactile maps serve as great aids for navigation and orientation, and 3D printing technology allows for the creation of customizable and high-precision tactile maps. In this project, we design, and 3D print tactile maps for the Engineering Campus at UW-Madison. In the design phase, we generate the CAD model of the area of interest while considering factors that aid and enhance usability of tactile maps such as incorporating braille text to identify buildings, scaled representation of the elevation (heights) and design based on recommendations from the American Disabilities Act (ADA). For the manufacturing process, we will consider FDM vs SLA printing options on preliminary designs of tactile maps to evaluate the part properties and to identify commonly encountered issues such as warpage. Once the design and manufacturing choices are finalized, we further explore opportunities for optimizing material usage and infill for faster and economical printing of tactile maps.

Preliminary Design

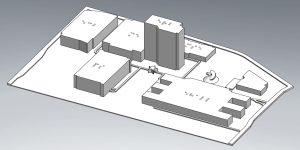

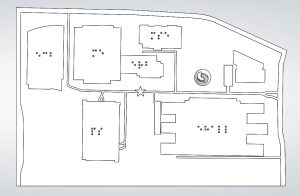

For our initial design we used the UW-Campus map to create a 2-D layout of the engineering campus. This is parametrically modeled in SolidWorks allowing for quick adjustments to build height and scaling as needed based on manufacturing and usability feedback we receive. The primary paths around the campus are modeled as raised platforms from the base to allow for identification of the local path you are on within the set of buildings. Surrounding roads are also mapped and extruded. Each Engineering campus building has an identifying acronym labeled on its top surface in Braille according to Braille reference data [1]. Additional Tactile Navigation map symbols and map features can be added according to recommendations made by the Journal of Blindness Innovation and Research after initial runs are completed [2].

Useful tools also exist to quickly develop tactile maps from street addresses, albeit with less detail and versatility in modifying the design to meet ADA and manufacturing requirements. For example, the site Touch-Mapper allows for quick 3D map models [3]. These models could be used with our tactile map idea to quickly develop models for a large area without having to create a detailed model for each area.

Figure 1: Initial Design for a Tactile Map of the Engineering Campus depicting Braille and “You Are Here” Identifiers.

Figure 2: Top View of the Tactile Map. To scale with the UW Campus Map [4].

Proposed Trials and Manufacturability and Usability Considerations

For our tactile maps of the Engineering Campus, we have decided to run a few trials related to designing for manufacturability but will focus more heavily on designing for usability. In terms of manufacturability, the main issue that we are concerned with is warpage in the final part. To determine whether warpage in the final part will be an issue for us, we will run two preliminary trials of our tactile map created from our SolidWorks 3D model of the Engineering Campus at a 0-degree print orientation. One will use a PLA material on an FFF printer, and the other will use a Formlabs Resin on an SLA printer, which will require scaling down the map size due to the smaller print area of available SLA printers. These two trials correspond to trial numbers 1 and 3 in Table 1 below. If we find that warpage is indeed an issue with these parts, we will then run trials 2* and 4* in Table 1 at a 45-degree print orientation, only if necessary to save time and materials.

Table 1: Outline of first print trials to be run (* indicates that the trial will only be run if necessary).

| Trial Number: |

Design: |

Process: |

Material: |

Variable: |

|

1 |

Preliminary – Engr. Campus | FFF | PLA |

Print Orientation: 0-degrees |

|

2* |

Preliminary – Engr. Campus | FFF | PLA |

Print Orientation: 45-degrees |

| 3 | Preliminary – Engr. Campus | SLA | Formlabs Resin |

Print Orientation: 0-degrees |

| 4* | Preliminary – Engr. Campus | SLA | Formlabs Resin |

Print Orientation: 45-degrees |

Depending on the results of these first trials to determine warpage issues, additional trials may be conducted to find an optimal print orientation to minimize warpage.

In terms of designing for usability, the main variables that we are interested in exploring are print material, overall print height, and whether braille will be incorporated for the building names. The print material is important to consider since those who are visually impaired will rely on an incredibly accurate surface for them to touch to determine their location and surroundings. Trials 1 and 3 in Table 1 above use two different materials and printing processes to address this variable early in the experimentation process. Later trials may also include experimenting with layer height to ensure that the surfaces are smooth and do not have any defects that could take away from the accuracy of the map. We are also interested in experimenting with the height of our buildings on our tactile map and attempting to make them scalable to the number of stories in each of the buildings on Engineering Campus. The overall height of the buildings on our tactile map will depend on the print time for the part as we would like to limit it to eight hours or less, but our initial idea for the building heights is to have one story correspond to 3 mm. The buildings on Engineering Campus, their respective number of stories, and the initial approximate tactile map building height are outlined in Table 2 below.

Table 2. Preliminary outline of the tactile map building heights for the Engineering Campus.

|

Engineering Campus Building: |

Number of Stories: | Approximate Tactile Map Building Height: |

|

Engineering Centers Building (ECB) |

4 |

12 mm |

|

Mechanical Engineering (ME) |

4 |

12 mm |

|

Engineering Research Building (ERB) |

14 |

42 mm |

|

Material Science & Engineering (MSE) |

2 |

6 mm |

|

Engineering Hall (E-Hall) |

3 |

9 mm |

| 1410 Engineering Drive | 2 |

6 mm |

The last usability variable that we are interested in looking into is whether to incorporate braille letters on top of the tactile map buildings to provide a name for each building. Implementing this variable would be one of the last steps in our project and would need to involve making sure that we follow ADA guidelines for braille spacing and height [3].

In addition to these intended variables that we will experiment with, we may also need to run trials at varying layer heights and infill percentages to create a smooth surface and maintain a print time of eight hours or less.

References

[1] Accent Signage Systems, Inc. (2012). Quick reference guide to ADA signage.

[2] Lobben, A. (2015). Tactile Maps and Mapping. Journal of Blindness Innovation and Research, 5(1).

[3] Kärkkäinen, S. (n.d.). Touch Mapper. Touch Mapper – Tactile Maps for the Visually Impaired. Retrieved February 27, 2022, from https://touch-mapper.org/en/

[4] University of Wisconsin–Madison Campus Map. Campus Map. (n.d.). Retrieved February 27, 2022, from https://map.wisc.edu/s/x801uir5