John Davern, Duncan Charlesworth, Arya Kamrani

University of Wisconsin-Madison

Abstract

This study aims to find a natural rubber blend (NR) suitable for extrusion-based additive manufacturing processes by focusing on the stress relaxation time of the material prior to vulcanization. A novel blend created by the Polymer Engineering Center at the University of Wisconsin-Madison was used as the framework for the study. It was found that increased concentrations of paraffin oil within the NR blend effectively decreased the stress relaxation time. Further research was done to better understand the processing conditions that are suitable for the material, and the implications of this research within the greater picture of NR additive manufacturing are discussed.

Project Overview

Natural rubber (NR) shows great potential in becoming a more sustainable alternative to the materials currently being used in the athletic footwear industry. Soan Laboratories, a Colombian research institute, recently patented a fabrication method that produces ammonia-free NR. It is a low cost, nontoxic material with excellent mechanical properties. The material’s avoidance of ammonia is also particularly attractive, as allergic reactions to ammonia have deterred the use of NR in wearable products.

The Polymer Engineering Center (PEC) is working with Soan Laboratories to characterize the ammonia-free NR and determine the necessary additives to allow for the material’s use in additive manufacturing (AM). For the past couple of months, the PEC has been experimenting with different blends of NR with the intentions of using Artificial Intelligence to predict viscoelastic properties of NR. Adidas Ultraboost material is currently being used as a reference for the desired mechanical properties that are to be replicated with NR. This project will focus on finding a blend with a suitable stress relaxation time for extrusion-based AM methods.

Research Considerations

To use natural rubber blends for extrusion-based AM processes, the material’s stress relaxation behavior must be carefully documented. If not given enough time to relax, polymer molecules will show a tendency to spring back to their original state. A Deborah number of less than 1, which is defined as the ratio of relaxation time over process time, is necessary to prevent melt fracture as the melt leaves the nozzle. 3D printed NR parts would have to undergo a post-process cure; therefore, the stress relaxation experiments should be conducted on samples before curing as the material should not undergo vulcanization during extrusion.

There have been a handful of attempts to use elastomers in the world of additive manufacturing. One previous method, first presented in 2015, used a robot equipped with a set of jet nozzles that sprayed drops of silicon onto a building platform. These drops were then vulcanized layer by layer with UV light and platinum-catalyzed addition curing [1]. Another process, presented in a 2016 study, attempted to deposit a continuous thread of material, while using similar curing methods [1].

A study by Wittek et al. proposed using an FFF process that would print the material in two pieces: a crude rubber/elastomer compound and a thermoplastic cast that is there to keep the rubber compound in its desired shape. This cast would eventually break off, with pre-determined breaking points having been printed into its design. Curing would take place in a high-pressure autoclave in a later step in the process [1]. The end goal of the project would be for the PEC to expand upon this research so that NR can be extruded in a pellet-based AM method, without the need of any support material.

Additives

This project will focus on determining the stress relaxation time of an uncured NR blend formulated by the PEC research group. The base formulation in parts per 100 (pph) with respect to NR was:

Table 1. Base formulation created by PEC group prior to start of project.

| Component Name | PPH |

| NR | 100 |

| Zinc Oxide | 5 |

| Stearic Acid | 1 |

| Sulphur | 2.5 |

| Tetramethylthiuram Disulfide (TMTD) | 1 |

Zinc oxide, stearic acid, and TMTD are used to activate the vulcanization reaction between Sulphur and NR. Paraffin oil was introduced to decrease the viscosity and stress relaxation time of the base NR mixture. Natural rubber degrades over time due to oxidation, which alters the mechanical and physical properties of the material. To use NR in AM applications, it would be ideal to use less activating/accelerating additives to widen the processing window for the NR during extrusion, and an antioxidant could make this possible. Trimethyl quinoline (TMQ) was added to blend based off the findings from a study conducted in 2011 by?Komethi et al. [2].

Figure 1. From left to right: Natural rubber, Sulphur, Paraffin Oil, and blend of Stearic Acid, Zinc Oxide, and TMTD.

Design of Experiments

The influence of paraffin oil on the NR blend was the driving factor behind the design of experiments (DOE) for this project. Paraffin oil is a plasticizer that creates more free volume between molecules, making it easier for the molecules to slide past each other. The alternative to adding a plasticizer is increasing the temperature of the material, but this approach could lead to premature vulcanization. The four quantities of paraffin oil that were examined were 50, 65, 75, and 80 pph. These concentrations were selected based on a related study conducted at Prince of Songkla University in Thailand aiming to optimize natural rubber footwear applications, in which 82 pph of paraffin oil resulted in an optimal blend for reducing impact force [2]. Table 2 depicts the formulation of each blend in terms of pph with respect to NR. Two blends (3 & 10) were conducted with 0.5 pph TMTD with the intention to delay the vulcanization activation and open the processing window.

Table 2. DOE in terms of pph with respect to NR.

| Blend No. | NR | Zinc Oxide | Stearic Acid | Sulphur | TMTD | Paraffin Oil | TMQ |

| 2 | 100.0 | 5.0 | 1.0 | 2.5 | 1.0 | 65.0 | 1.0 |

| 3 | 100.0 | 5.0 | 1.0 | 2.5 | 0.5 | 65.0 | 1.0 |

| 6 | 100.0 | 5.0 | 1.0 | 2.5 | 1.0 | 75.0 | 1.0 |

| 8 | 100.0 | 5.0 | 1.0 | 2.5 | 1.0 | 50.0 | 1.0 |

| 9 | 100.0 | 5.0 | 1.0 | 2.5 | 1.0 | 75.0 | 1.0 |

| 10 | 100.0 | 5.0 | 1.0 | 2.5 | 0.5 | 75.0 | 1.0 |

| 11 | 100.0 | 5.0 | 1.0 | 2.5 | 1.0 | 80.0 | 1.0 |

Approach

Mixing

The base NR blend (Table 1) was mixed under a set procedure in which the rubber was placed in the Brabender mixing machine for 8 minutes, followed by 2 minutes to mix in the TMTD, zinc oxide, and stearic acid, and 1 minute to mix in the sulfur. Once all the components were in the Brabender, the machine would mix for an additional 7 minutes to ensure a cohesive blend.

It was anticipated that the paraffin oil would disrupt this process, as initial trials revealed a tendency for the rubber pieces to slide past each other when oil was introduced. The procedure that yielded the best results is as follows:

- Place all the rubber into the Brabender mixer. Starting operating conditions are 50 rpm at room temperature. (? 5 min)

- Mix all the additives together with the paraffin oil except for sulphur.

- With the Brabender mixer closed, reduce speed to 10 rpm and pour a small amount of the oil mixture into the hopper area. Open and close the Brabender to introduce the oil to the rubber. With oil inside, increase speed back to 50 rpm. Repeat this process until the oil mixture is completely inside. (15?20 min)

- Increase temperature to 60C.

- Let the rubber and oil mix for about 10 minutes. Vary the speed from 50-100 rpm to prompt dispersive mixing.

- When the oil appears to be setting into the rubber (?40-45 min mark), begin to introduce the sulphur. Reduce the Brabender to 10 rpm while opening the mixer to do so. Vary from 10-50 rpm, such as Step 3, to evenly introduce the sulphur.

- Cool the Brabender down to 45C once the sulphur has been added.

- Vary the mixing speed from 50-100 rpm until the blend becomes cohesive. The torque will level off once this has been achieved. (?10-40 min)

An increase in paraffin oil concentration directly translated to a longer mixing time. Approximately, it would take about 60 min to mix 50-65 pph oil, 75-90 min for a 75 pph mixture, and upwards of 110 min for 80 pph oil. Repetitions of the blends were made to ensure that mixing times above 60 min did not affect the relaxation time or curing behavior. While the oil caused the mixing time to increase, the detrimental effects of over-masticating the material were negated since shearing stresses did not reach a critical level. Rheometer testing proved that 60 C would not induce a premature cure. In general, this procedure should act as a guideline for future mixing but is subject to adaptations as deemed necessary.

Figure 2. The natural rubber blend once mixed in the Brabender.

Material Characterization

After preparing each batch of uncured blends as described in Table 2, the curing and viscoelastic properties of each blend were analyzed. These material properties will be used to determine the optimal processing time and temperature for NR in extrusion-based-AM applications for future experiments. In the interest of comparing each blend as a viable material for extrusion, it was necessary to quantify a cure temperature, stress relaxation time, and cure time for each blend. These properties would be characterized through differential scanning calorimetry, parallel plate rheometry, and melt-flow indexing.

Parallel-plate Rheometry

The parallel-plate rheometer at the Wisconsin Institute of Discovery was used to characterize both curing behavior and the stress relaxation for each blend (Figures 3 and 4). Cure time was characterized with the rheometer by imposing an oscillatory strain of 0.2% at 1 Hz. while recording G’, tan, and the oscillatory stresses over a period of time for a given isothermal state. Isothermal behavior at 60C was characterized to ensure no vulcanization would occur at 2 hours. Relating to our prolonged mixing time, 100C was also tested to allow for an alternative temperature if residence times would exceed the curing time at 120C. 120C would be characterized to understand the time needed for the material to vulcanize if left in the extruder for too long. Finally, 150C was characterized to quantify the curing time for the post-cure process. For stress relaxation, multiple cylindrical samples from each blend would undergo 1% strain while the shear stress was recorded over a period of time. Typically, stress relaxation would be defined as the time required for the sample to relax within 1% of the initial stress, but a 5%-max-stress threshold was used to address the appreciable noise below this range.

Figure 3. Parallel-plate rheometry test set up.

Figure 4. Rubber test specimen after stress-relaxation test.

Differential Scanning Calorimetry

Observing the effect of the additives on the cure rate would require the use of differential scanning calorimetry (DSC). Samples were subjected to constant heating rates to record the heat flow of vulcanization. As heat flow is a proxy for the cure behavior in crosslinked polymers, graphs were produced comparing the heat flow of blends with varying amounts of activator additives (i.e. TMTD).

Melt-Flow Indexer

Samples were placed in an MFI machine to observe the flow rate in respect to pph of paraffin oil. The method was adapted from the International Standard ISO 11133-1 and was used to observe the extrusion behavior for each blend [3]. Samples were heated to an expected processing temperature of 120 C for 2 minutes, and then a 2.16 kg weight was used to apply force for 5 minutes. At the end of the test, samples were weighed and extrapolated to represent a 10-minute test as 10 minutes would most likely cause vulcanization.

Results

Curing Characterization

Cure Time – Parallel-Plate Rheometry

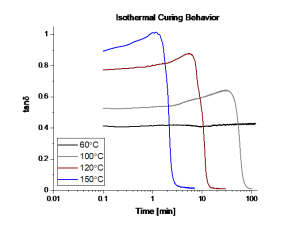

Oscillatory strains of 0.2% were imposed on uncured NR mixture samples at 1 Hz at 60C, 100C, 120C, 150C. Most isothermal curing was conducted on a single blend, as the paraffin oil concentration generally did not affect the start time of the cure. The cure behavior for Blend 10 – a 75 pph batch – is shown in Figure 5 below.

Figure 5. Isothermal curing behavior of NR blend.

The beginning of a cure is indicated by the onset of the tan curve, a metric quantifying a material’s ability to absorb energy. This occurred at 1 minute at 150C, 10 minutes at 120C, and 30 minutes at 100C. The blend approached cure completion near 3 minutes at 150C, 11 minutes at 120C, and 80 minutes at 100C. No noticeable curing was detected at 60C, indicating that the mixing process did not cause noticeable vulcanization.

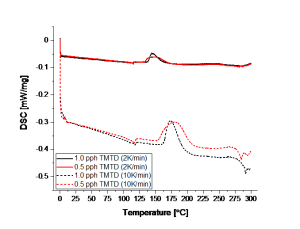

TMTD Behavior– DSC

Blends 2 and 3, which had 1.0 pph and 0.5 pph TMTD respectively, were placed in a DSC at varying heating rates to observe the effect of TMTD on the blend. The solid lines in Figure 6 show the reaction that took place with a 2K/min heating rate, while the dashed lines represent a 10K/min heating rate. It is noticeable in both cases that the higher amount of TMTD caused a quicker exothermic reaction compared to a blend with less TMTD. The higher heating rate of 10K/min carry a larger thermal inertia which result in an amplified signal. This amplified signal is evident when comparing the magnitude of the curves for varying heating rates. It is evident that a higher thermal inertia may cause overshooting or undershooting which results in noise. This noise is responsible for causing the discrepancies between both sample curves which is noticeable in a 2K/min heating rate.

Figure 6. DSC data from Blends 2 and 3 reveal the impact of TMTD on the exothermic reaction behavior.

Melt Flow Characterization

Stress Relaxation – Parallel Plate Rheometry

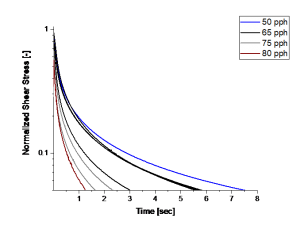

The 1%-strain stress relaxation test was completed for each of the blends, each undergoing three repetitions of the test. Data was recorded in each trial until the stress fell below 1% of the initial stress value. The stress response of all samples was normalized with respect to the maximum stress and averaged with respect to each blend. These responses are shown in Figure 7 below.

Figure 7. Stress relaxation times for the blends in the DOE.

Table 3: Summary of 5% Stress Relaxation

| Paraffin Oil Mass Ratio [pph] | Stress Relaxation Time |

| 50 | 7.5 |

| 65 | 5.6 |

| 75 | 2.33 |

| 80 | 1.2 |

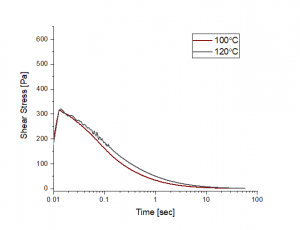

As these tests were completed below curing temperature, only the mass ratio of paraffin oil had a noticeable effect on the stress relaxation behavior of the uncured samples. As anticipated the blends with more paraffin oil had lower relaxation times. Blend 11 (80 pph paraffin oil) had the shortest time, taking an average of 1.2 seconds to drop below 5% of the initial stress (Table 3). Further experiments conducted on Blend 11 revealed similar stress relaxation behavior at both 100C and 120C (Figure 8).

Figure 8. Stress relaxation times for the blends in the DOE.

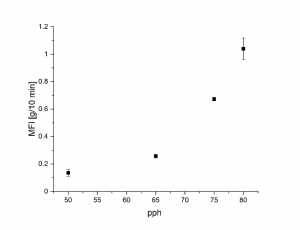

Melt Flow Indexing

The results from the MFI are depicted in Figure 9. A noticeable upwards trend in ease of flowability is evident as the concentration of paraffin oil increases. To feasibly use NR in extrusion-based AM applications, the material needs to be able to extrude in a timely manner, otherwise the value of the technology is diminished. Increasing the amount of paraffin oil not only reduces the stress relaxation time but improves the flowability of the material as well. Figure 10 shows Blend 11 as it is halfway through the MFI test. The 2.16 kg weight produced a smooth extrudate, and while the hopes are not to use this material in a force-based AM application, it was reassuring to see the possibility of a smooth product. Figure 11 shows the result of using excessive force to clear the MFI chamber, which resulted in melt fracture.

Figure 9. Melt flow rate in grams/10 min with respect to paraffin oil level.

Figure 10. Blend 11 halfway through the MFI test.

Figure 11. Self-induced melt fracture on the MFI sample.

Discussion

The goal of this study was to find a NR blend suitable for extrusion-based AM applications. The approach used in this project determined that increasing the amount of paraffin oil in a NR blend decreases the stress relaxation time, and that a suitable processing window can take place at 120C.

Mixing the rubber and paraffin oil together proved to be the most difficult aspect of this project. The guidelines outlined in the Approach section proved to be the best method for the additives that were being used in this study, however, the process itself is prone to human error. There is reassurance in the fact that industries often test each blend individually for curing and melt characteristics in order to optimize the AM process. This would have to be the case during the early stages of printing the NR blend as variations in the stress relaxation time are evident in Figure 7. Nonetheless, the trend exists in which increasing the paraffin oil decreases the stress relaxation time, which was the primary focus of this project.

Changing the level of TMTD can alter the processing window for extrusion. More TMTD with respect to NR leads to a quicker exothermic reaction; therefore, if the level of TMTD is decreased it will create more time for the blend to undergo the extrusion process. The faster heating rate revealed signal overshoot, however, faster heating rates are typically used in industry. The DSC experiments are useful in their current state but can be expanded upon by testing more variations of TMTD to ensure that the trend persists.

Qualitatively speaking, the blends became substantially more malleable as the paraffin oil level increased. In fact, the samples that were run through the MFI exhibited a tackiness that is desirable for AM as adhesion between layers is crucial. Cured samples from the parallel-plate rheometry testing could be stretched with a significant amount of force and still return to their original shape. All in all, the witnessed behavior of the samples was indicative of the desirable behaviors for 3D printing.

Given the information found in this study, the ideal situation for 3D printing would be as follows:

- Mix necessary additives into NR to decrease stress relaxation time.

- Insert the blended material into extrusion-based 3D printer.

- Allow the screw fed system to 3D print the material onto the bed without any vulcanization occurring.

- Cure the fully printed part at 150 C during post processing.

Future Work

Four more blends were mixed during this project that were later rejected during the testing phase as they appeared to be outliers in the data. The formulations in pph are as follows:

Table 4. Rejected blend formulations in terms of pph with respect to NR.

| Blend No. | NR | Zinc Oxide | Stearic Acid | Sulphur | TMTD | Paraffin Oil | TMQ |

| 1 | 100 | 5.0 | 1.0 | 2.5 | 1.0 | 65.0 | 0.0 |

| 4 | 100 | 5.0 | 1.0 | 2.5 | 1.0 | 65.0 | 2.0 |

| 5 | 100 | 5.0 | 1.0 | 2.5 | 0.5 | 65.0 | 2.0 |

| 7 | 100 | 5.0 | 1.0 | 2.5 | 0.5 | 75.0 | 1.0 |

These blends should be reassessed and mixed again, as this stage of the process is susceptible to human error. The levels of both TMQ and TMTD vary amongst these blends and should be monitored throughout this second wave of testing. Comparisons between Blends 4 and 5, and 6 and 7, in the DSC can offer more evidence whether the TMTD observations remain consistent across blends. Due to the results seen in Figure 8, more blends should undergo a 100C stress relaxation test to see if the trend observed in Blend 11 is valid for all cases. If so, the extrusion processing temperature could take place at 100C, reducing the risk of premature vulcanization significantly.

Naturally, once the blend is finalized with the desired properties, the work shifts to figuring out the logistics of 3D printing the material. The PEC will produce the mixtures of the blend and ship them to Fused Form, a Columbian-based 3D printing manufacturer. Fused Form has recently created a new product named the FF Pellet 600+, which is capable of large-format pellet extrusion [4]. While the PEC is the first Fused Form client to receive one of these new printers, Fused Form has agreed to start initial testing so that ongoing research can continue at the PEC. The combination of the FF Pellet 600+, and the correct blend of NR, has the potential to open new avenues for sustainable material additive manufacturing.

Acknowledgments

We would like to recognize the staff of the Polymer Engineering Center at UW – Madison for accommodating for our use of their facilities. Access to PEC instrumentation was essential for the research required of this project. We would also like to thank Allen Román, Chief Engineer at the UW Polymer Engineering Center, for his contributions as the main advisor to this project.

References

[1] H. Wittek, B. Klie, U. Giese, S. Kleinert, L. BIndszus, and L. Overmeyer, “Approach for additive Manufacturing of high-viscosity, curable Rubbers by AME Processing (Additive Manufacturing of Elastomers) – Rubber 3D,” Mach. Equip., pp. 53–54, 2019.

[2] M. Komethi, N. Othman, H. Ismail, and S. Sasidharan, “Comparative study on natural antioxidant as an aging retardant for natural rubber vulcanizates,” J. Appl. Polym. Sci., vol. 124, no. 2, pp. 1490–1500, 2012, doi: https://doi.org/10.1002/app.35160.

[3] “ISO 1133-1 — Determination of the melt mass-flow rate (MFR) and melt volumeflow rate (MVR) of thermoplastics.” ISO, 2011, Accessed: May 05, 2021. [Online].

[4] “Fused Form Develops Colombia’s First Large-Format Pellet 3D Printer,” 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing, Mar. 22, 2021. https://3dprint.com/279694/fused-form-develops-colombias-first-large-format-pellet-3d-printer/ (accessed May 04, 2021).