Updated Design

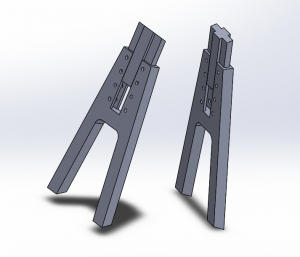

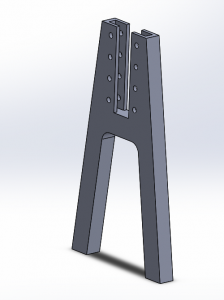

The updated design for our bicycle consists of two separate pieces. The main stand and a sliding component that slots into the top section of the stand. The sliding component allows for height adjustment of the stand by using a pin to secure the holes at the desired height. The main stand is 11 inches and the sliding component can add 3 more inches, which helps encompass different sized bikes. A single assembly of our design can be used to prop up the back tire of a bike with the balance of the front tire. The addition of a second assembly can eliminate the need of the front tire to balance. Images of the full assembly as well as the individual parts can be seen below in Fig.1 and Fig.2 respectively.

|

| Figure 1. Full Assembly of Parts |

|

|

|

Figure 2. Base part (left) and sliding adjuster (right) |

|

Print Trials

The part was completed using FFF printing on an Ultimaker 3D printer. Our material of choice was nylon due to its durability. Through further research, we also finalized our choice of nylon because of its resistance to corrosion of common chemicals and alkalis as well as its resistance to humidity.

The print time for the full-scale piece was 24 hours so we decided to print a half-scale model to reduce the print time. The half-scale prototype had a print time of 5.5 hours. Print time was further optimized by the use of a 20% interior mesh and 0.2 thickness layers. To reduce the amount of support structures needed both pieces were oriented flat on the print bed.

Results

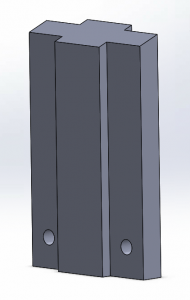

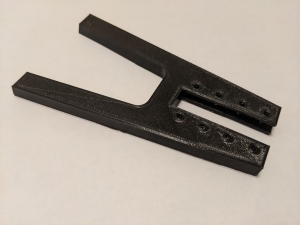

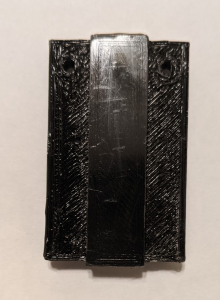

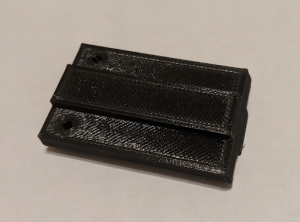

Due to the nature of FFF printing, some surfaces and edges had poor quality. Also, the holes in the main stand became a little crowded with extra material. The bike stand assembly is unable to be tested properly as the pieces do not fit together correctly due to poor tolerancing. The print results for the main stand and sliding component are shown below in Figures 3 and 4, respectively.

|

|

| Figure 3. First print of main stand. | |

|

| Figure 4. First print of sliding component. |

Future Considerations

Moving forward, our next step is to adjust the tolerances on the Solidworks designs and do another print such that testing is able to be completed properly. Additionally, the next print scale will be maximized to fit an 8 hour print window, to better allow testing using a children’s bike. To actually test our prototype our goal is to be able to use the stand on a children’s bicycle and successfully lubricate the chain and elevate the wheels off the ground. The next trial will also use a thinner print layer for a more accurate part. Finite element analysis will be completed on this design to analyze critical stresses during use. This analysis will be performed with the load from an average mountain bike (25 lbs).

This design could be further iterated upon to better fit the average bike. In the improved design, the top could be made rounded to better fit a bike.