Progress Update

Mixing

The base NR blend was mixed under a set procedure in which the rubber was placed in the Brabender mixing machine for 8 minutes, followed by 2 minutes to mix in the TMTD, zinc oxide, and stearic acid, and 1 minute to mix in the sulfur. Once all the components were in the Brabender, the machine would mix for an additional 7 minutes in order to ensure a cohesive blend. It was anticipated that the paraffin oil would disrupt this process; introducing the oil to the blend would require some adjustments to the mixing procedure. 50 pph of paraffin oil was used in the first batch, as this was the lowest volume of oil in our original experiment design.

For the first trial, oil and rubber were successively added to the mixture in small increments until each ingredient was introduced entirely. Once the oil was in the Brabender, the mastication process slowed noticeably as the rubber pieces became lubricated and started sliding past each other. After increasing the temperature of the system from 21 C to 50 C, the blend was finally able to mix after about an hour inside the Brabender. A different approach was used in the second trial, in which the rubber and additives were mixed first, and then the oil was added last. This method proved unsuccessful, as two separate pieces of rubber formed around each screw as the oil pooled in between them. A video is attached below to demonstrate this issue. For the third trial we went back to the incremental method but started the mixing process at 50 C. To our surprise, the initial temperature rise did not seem to improve the processing time, and the first method proved to be the most successful.

Unfortunately, about a week after submitting our project proposal, the Brabender mixing machine had to be shipped out for maintenance. It was determined that the blade diameter had warped due to wear and tear. Luckily, our group was able to process three blends of NR (natural rubber) mixed with 50 pph paraffin oil prior to the maintenance setback. These samples were used in preliminary testing to characterize curing and stress relaxation behavior.

Testing

Curing Time/Temperature

In preparation for testing, a two-hour training session was held to acquaint us with the DSC. This involved the preparation of small NR samples used in the DSC, as well as an overview the testing process. There was also a brief introduction to the software needed to record the data. Calibration issues with the DSC would suspend further cure characterization, but this method will be used with NR mixtures prepared later in this project.

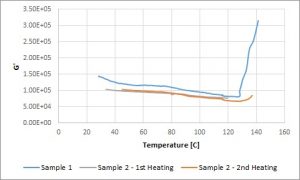

Instead, the cure temperature was estimated using a parallel plate rheometer. Samples of the 50 pph paraffin oil NR mixture were heated, and the shear modulus was recorded as a function of temperature as shown in Figure 1. Two samples were heated – sample one to 140 C and sample two to 120 C, both at 5 K/min.

Figure 1. Heating tests conducted on 50 pph paraffin oil sample.

Sample one showed a considerable increase in shear modulus at 130 C indicating that appreciable curing had occurred. Sample two was then heated to 120 C and showed no such rise in shear modulus. To ensure that sample two’s mechanical properties remained unchanged by this test, it was then cooled and reheated to 140 C. The behavior of this second heating trial was identical to the first through 120 C, showing that no significant curing had occurred in the first trial. 120 C would therefore be used as a processing parameter for stress relaxation tests, however, it still must be determined whether the NR mixture can remain at this temperature for extended durations without curing.

Stress Relaxation

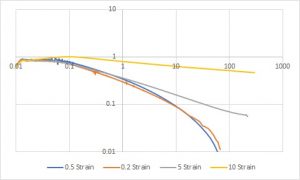

Residence time is critical to polymer processing, as it determines the amount of time that a polymer has to relax before extrusion. To determine the minimum process time for the NR mixtures, a parallel–plate rheometer was used to find its relaxation time. The plot below shows the stress relaxation behavior of the 50 pph paraffin oil mixture at 120 C at various strain rates (Figure 2).

Figure 2. Stress relaxation behavior of 50 pph paraffin oil sample.

For the 0.5% and 0.2% strain trials, the rubber mixture was able to relax to 1% of the initial stress within 67 seconds. The 5% and 10% strain trials did not see complete stress relaxation in this time window. Furthermore, while the NR mixture achieved near complete relaxation for lower strain rates, this period would be a fairly long process time for extrusion applications. We would hope to see far shorter stress relaxation times in NR mixtures with more paraffin oil, as FFF materials, such as ABS, have shown relaxation times near 10 seconds at 0.5% strain at extrusion temperatures [1].

Future Research

Additives

Natural rubber degrades over time due to oxidation, which alters the mechanical and physical properties of the material. Since our mixing trials were delayed due to maintenance, our group decided to focus on finding an antioxidant that could help slow the oxidation process. Ideally, we would like to use less activating/accelerating additives to widen the processing window for the NR during extrusion, and an antioxidant could make this possible.

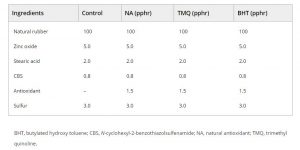

A study conducted in 2011 by Komethi, Othman, Ismail, and Sasidharan titled “Comparative study on natural antioxidant as an aging retardant for natural rubber vulcanizates” became of great interest to our group. Palm oil, a natural antioxidant, was compared to two commercial antioxidants, trimethyl quinoline (TMQ) and butylated hydroxy toluene (BHT), in order to analyze their effects on the aging process of NR. This study examines a similar base blend to the one that our group is using, suggesting that results from the study could translate to our own blend. Figure 3 below shows how NR was mixed with zinc oxide, stearic acid, sulfur and CBS, whereas our group was using TMTD instead of CBS (Figure 4).

Figure 3. Antioxidant test comparison blends found in literature[2].

| Component Name | PPH |

| NR | 100 |

| Zinc Oxide | 5 |

| Stearic Acid | 1 |

| Sulphur | 2.5 |

| Tetramethylthiuram Disulfide (TMTD) | 1 |

Figure 4. Base blend our group is adding TMQ to.

While palm oil was found to be a suitable substitute to commercial agents, it was determined that it would work best in short term situations. This would not be suitable for our project, as NR extrusion for footwear would require long term resistance to aging degradation. Since TMQ exhibited better antioxidant activity in comparison to BHT, our group decided to purchase 10 grams of TMQ to add to our blend[2].

Test Plan

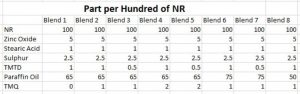

The test plan is shifting from testing 50, 60, 70 and 80 pph of paraffin oil to the eight-blend test plan as outlined in Figure 5. Given the laborious nature of preparing NR-paraffin oil mixtures, we will reduce the scope of the experiment from four to three different mixtures (50, 65, and 75 pph paraffin oil). Simultaneously, we will be monitoring the effect that TMQ has on the blend. Blends 1-5 will introduce 0, 1, and 2 pph TMQ to characterize the antioxidant’s effect on the stress relaxation time of the 65 phh paraffin oil–NR blend. Blends 6 and 7 will test 75 pph of paraffin oil with 1 pph of TMQ, and the last blend will test 50 pph of paraffin oil one last time with 1 pph of TMQ. With the Brabender expected to return to the Polymer Engineering Center the week of 4/12/2021, it will be crucial that mixing commences immediately to have enough time to conduct DSC and rheometer analysis. As previously mentioned in the proposal, the goal remains find the blend with the shortest relaxation time so that NR can be used in extrusion-based additive manufacturing.

Figure 5. Blend combinations that will be tested before the end of the semester.

References

[1] A. Saadat, H. Nazockdast, F. Sepehr, and M. Mehranpour, “Linear and nonlinear melt rheology and extrudate swell of acrylonitrile-butadiene-styrene and organoclay-filled acrylonitrile-butadiene-styrene nanocomposite,” Polymer Engineering & Science, vol. 50, no. 12, pp. 2340–2349, 2010, doi: https://doi.org/10.1002/pen.21769.

[2] M. Komethi, N. Othman, H. Ismail, and S. Sasidharan, “Comparative study on natural antioxidant as an aging retardant for natural rubber vulcanizates,” Journal of Applied Polymer Science, vol. 124, no. 2, pp. 1490–1500, 2012, doi: https://doi.org/10.1002/app.35160.