Project Overview

Natural rubber (NR) has great potential in becoming a more sustainable alternative to materials currently being used in the athletic footwear industry. Soan Laboratories, a Colombian research institute, recently patented a fabrication method that produces ammonia-free NR. It is a low cost, nontoxic material with excellent physical properties. The material’s avoidance of ammonia is also particularly attractive, as allergic reactions to ammonia have deterred the use of NR in wearable products.

The Polymer Engineering Center (PEC) is working with Soan Laboratories to characterize the ammonia-free NR and figure out the necessary additives to allow for additive manufacturing (AM) possibilities. For the past couple of months, the PEC has been experimenting with different blends of NR, with the intentions of replicating the mechanical properties found in Adidas Ultraboost material. This project will focus on finding a blend with a suitable stress relaxation time for extrusion-based AM methods.

Research Considerations and Material Choice

To use natural rubber blends for extrusion-based AM processes, the material’s stress relaxation behavior must be carefully documented. If not given enough time to relax, polymer molecules will exhibit a spring back behavior to their prior state. It is vital that the stress relaxation time is shorter than the process time otherwise the melt will fracture as it leaves the nozzle. 3D printed natural rubber parts would have to undergo a post-process cure, therefore, the stress relaxation experiments should be conducted on samples below the curing temperature.

This project will focus on the stress relaxation time of an uncured NR blend formulated by the PEC research group. Currently, the base formulation in parts per 100 (pph) with respect to NR is:

| Component Name | PPH |

| NR | 100 |

| Zinc Oxide | 5 |

| Stearic Acid | 1 |

| Sulphur | 2.5 |

| Tetramethylthiuram Disulfide (TMTD) | 1 |

Zinc oxide, stearic acid, and TMTD activate the vulcanization reaction between Sulphur and NR. To decrease the viscosity and stress relaxation time of the current NR mixture, paraffin oil will be introduced into this formulation. The first step for our project will be determining an effective mixing procedure involving the paraffin oil. Three previous attempts found that incrementally mixing 50 pph paraffin oil into the blend structure yielded a testable compound. This required an increased processing temperature (21 C to 60 C) and processing time (18 to 60 minutes) compared to the paraffin-free rubber.

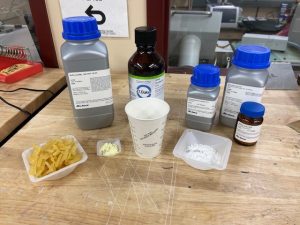

Figure 1. From left to right: Natural rubber, Sulphur, Paraffin Oil, and blend of Stearic Acid, Zinc Oxide, and TMTD

Figure 2. The natural rubber blend once mixed in the Brabender.

Proposed Analysis

The primary objective of this project is to create a natural rubber blend that can be extruded smoothly in a timely manner without vulcanizing it or creating melt fractures. Stress relaxation times in NR blends with varying amounts of paraffin oil will be measured with the use of a rheometer. Four variations of the blend will be tested with 50, 60, 70, and 80 pph in respect to the NR. These amounts were selected based off a related study conducted at Prince of Songkla University in Thailand aiming to optimize natural rubber footwear applications, in which 82 pph of paraffin oil resulted in an optimal blend for reducing impact force [1]. Once the four samples have been mixed, a piece of each one will be placed in a DSC (differential scanning calorimeter) in order to find the curing temperatures. This is a crucial step as it sets the upper boundary for the processing temperature window. Once the curing temperatures have been determined, the rubber blends will be placed into a parallel plate rheometer to find the stress relaxation time. The blend with the shortest relaxation time will be used by the PEC group to conduct preliminary extrusion-based AM tests.

References

[1] S. Srewaradachpisal, C. Dechwayukul, S. Chatpun, R. J. Spontak, and W. Thongruang, “Optimization of the Rubber Formulation for Footwear Applications from the Response Surface Method,” Polymers, vol. 12, no. 9, Art. no. 9, Sep. 2020, doi: 10.3390/polym12092032.