Project Overview

The goal of the project is to replicate the watertight properties of SLA with a cheaper and more abundant process, FFF, in order to create a watertight cover for the electrical components for a dog assist cart for Professor Nellis’ dog Bronte. The electrical components are in a small box placed on the backside of the cart shown in Figure 1. The cover is necessary to ensure that the components do not get wet and short the circuit which could leave Bronte in a position where she is without a motorized assist or in danger from an electrical malfunction. Through this project, we will evaluate which additive manufacturing variables can be changed to make the most watertight custom electronics cover.

Figure 1: Bronte and the motorized assist cart.

Preliminary Design

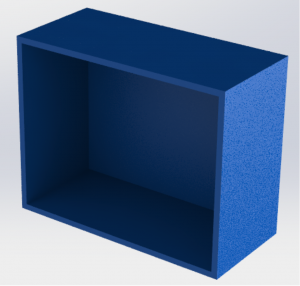

The design that we will be testing is shown in Figure 2. This design will be the approximate geometry used to enclose the electronics on the cart and will be printed using both FFF and SLA processes.

Figure 2: Isometric view of electronic cover to be printed.

The design is intended to fit tightly over a similar open box that the circuitry for the cart will be mounted on.

Manufacturing Considerations

The two additive manufacturing processes to be considered for the watertight cover are fused filament fabrication (FFF) and stereolithography (SLA). While FFF is a cheaper and more accessible process [1], SLA creates can create watertight parts more easily [2]. This is because SLA printers create chemical bonds between layers while the layers of FFF printers are mechanically bonded. This mechanical bond in FFF parts allows for more leakage between the layers [3].

For this project, we will compare the performance of covers made using FFF to that of a part made using SLA. The SLA part will serve as the control, and the printer settings and wall thickness of the FFF parts will be varied in an effort to replicate the watertight properties of the SLA part.

Initial Work

To test whether FFF parts could replicate the watertight nature of SLA parts, we will begin work by printing the initial design shown in Figure 1 using the processes and material shown in Table 1.

Table 1: Proposed Design matrix to compare the watertight performance of FFF parts, made with different materials, to the performance of the same SLA part.

| Design | Process | Material |

| 1 | SLA | Photopolymer Resin |

| 2 | FFF | PLA |

| 3 | FFF | PC |

| 4 | FFF | PP |

To replicate the application of the electronic cover on the motorized assist cart, the leakage through the part over two hours will be measured. This can be done by first noting the mass of the part. Next, the printed electronics cover can be filled with a cup of water and the total mass of the system can be recorded. The water can then be left in the part for two hours. At the end of two hours, the mass of the part and the remaining water can be measured. The difference between the initial and final masses of the part and water will indicate the amount of water that has leaked out of the part. Finally, the remaining water can be removed from the part and the final mass of the part can be taken. The difference between the final (part only) mass and the initial indicates the amount of water that was absorbed in the walls of the part.

This test will allow us to compare the watertight properties of the FFF parts printed with different materials to the SLA printed part. Once we determine which material yields the best properties, we will focus our attention on adjusting the process parameters of the FFF printer with that material. In doing this, we hope to replicate the water-tight properties of SLA with a cheaper FFF process.

Resources:

[1] “3D Printer Material Cost: The Real Cost,” All3DP, Sep. 08, 2020. https://all3dp.com/2/3d-printer-material-cost-the-real-cost-of-3d-printing-materials/ (accessed Mar. 02, 2021).

[2] Xometry, Will It Leak? 3D Printing Watertightness Test. 2016.

[3] “3D Printing Technology Comparison: FDM vs. SLA vs. SLS,” Formlabs.

https://formlabs.com/blog/fdm-vs-sla-vs-sls-how-to-choose-the-right-3d-printing-technology/ (accessed Mar. 02, 2021).