Project Overview

This project will design a multi-purpose bicycle maintenance stand that can act as a more stable kickstand as well as a device to prop up the back wheel of your bike. This will simplify performing regular maintenance tasks, like greasing your chain or pumping up your tire. Typically, riders flip the bike upside down to perform maintenance, however this device will eliminate the need to do that if you are physically unable to, or just prefer not to.

This is similar to a kickstand found on the Specialized Turbo Bike, as seen in Fig.1.

|

|

Fig.1. Specialized bike kickstand [1] |

However, our design differs from this image in three ways. First we are proposing to make the stand adjustable to different heights. Second it will be easily removable, collapsible and lightweight enough such that it can be carried in a backpack for long distance rides if the need to perform any maintenance arises. Finally, our maintenance stand will be able to lift the back wheel off the ground since the stand will have at least three points of contact with the ground.

Preliminary Designs and Manufacturing Considerations

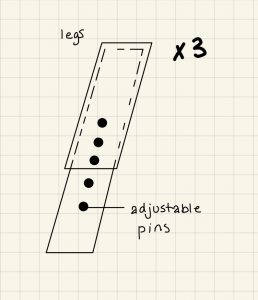

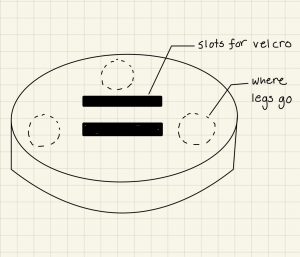

While considering the preliminary design we determined the maximum extension of our stand to be 14.5 inches. This is based off of a typical adult bike tire ranging from 24 to 27 inches. Our preliminary design includes a plate which can be secured to the bike frame using Velcro straps. Support tubes which raise the bike are attached to the plate through three holes. These support tubes are each two sections to allow for extension compatible with different bike sizes. We are also considering designs in which the legs fold and snap out into place, similar to those of a typical tripod.

A preliminary sketch of our design is shown below in Fig.2.

|

|

|

Fig.2. A preliminary sketch of the leg assembly (top) and mounting plate (bottom). |

|

We are proposing to print the parts necessary to build the stand using an FFF process. With the available printers in the Makerspace, the Ultimaker S5 would be the printer of choice. With a large build volume of 13 x 9.4 x 11.8 inches, there is more than enough space necessary to manufacture the individual parts. An important property to note is the anisotropic nature of parts printed using FFF. Because of this, our design will need to be careful to not put shear stress in the same direction of our printed layers. Since, the majority of the forces acting upon the legs of our device will be compressive forces, this is a minor problem.

Another design consideration is the type of material that will be used for this part. The ideal material will be tough, to withstand mild outdoor conditions, and will be stiff enough to support the weight of the bike. Looking at the available materials, Ultimaker Nylon will be our material of choice, and the material used in our first print trial. Ultimaker Nylon is the material of choice because it is both tough, as well as wear resistant, so it runs the least risk of wearing down from gravel and other road/ground materials.

Proposed First Print Trial, Experiments and Similar

The first print trial will see the first iteration of the bike stand printed in the Ultimaker S5. Since each leg is composed of two thin tubes, for a total of six leg tubes, we will print half the tubes vertically and half horizontally in order to evaluate which orientation produces the optimum results for our design. To determine necessary the fill ratio and layer thickness, we will perform an initial force analysis in ANSYS. Due to the adjustable nature of our part and it being multiple pieces, multiple prints may be required.

In experimentation, we will test the bike stand on a full-sized adult bike to ensure stability as a bike stand when adjusted to various heights, on various medium surfaces (grass, gravel, concrete), and on various grade surfaces (incline, level, and decline).

References

[1] T. Roehrkasse and C. Rye, “Specialized Turbo Review,” ElectricBikeReview.com, 04-Nov-2019. [Online]. Available: https://electricbikereview.com/specialized/turbo/