Explanation:

Foldable knives are a useful tool with a purpose in many settings, including both industrial and environmental applications as well as personal use. These knives are designed with two scales that are either riveted or screwed to one another to make up the handle. The complete handle can be made from a variety of materials to target different conditions and uses for various knives. For this project, the scales will be designed, optimized, and ultimately 3D printed in the UW-Madison Makerspace. The final product will minimize part assembly in the handle, optimize ergonomics, reduce weight, increase strength and durability, and improve finish quality. Along with the actual solid model, material selection and the chosen additive manufacturing process will play a large role in the final product quality.

Preliminary designs and manufacturing considerations:

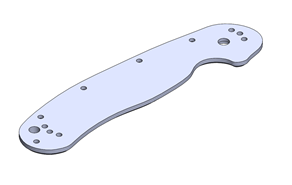

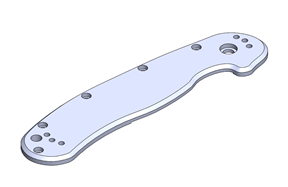

A preliminary SolidWorks model was created for the scales as seen in Figure 1. The scales are slightly different from one another due to the asymmetric nature of the lock inside the handle. The geometry closely mirrors the current handle design on this knife; however, this design will be optimized to improve the performance and manufacturability of the scales. This may be achieved using different surface patterns or experimenting with various polymer materials.

Figure 1: A solid model of each scale. The two parts will be fastened together, and a pivoting blade will be affixed between them.

The initial print will be done using fused filament fabrication (FFF) with Ultimaker nylon. This proprietary nylon polymer has high strength and resistance to water and other environmental factors that may affect knife users. The final print will use stereolithography (SLA) with Formlabs Rigid resin. This material was chosen due to its high strength and stiffness, along with surface finish quality. Printing using two different materials and additive manufacturing methods will allow for comparison between the parts and different features of each process.

Proposed first print trial and experiments:

The first planned print will be carried out using nylon on an Ultimaker FFF printer. The simplicity of FFF makes this initial step easy to implement and test manufacturing capabilities. Adequate material properties allow proper analysis to be performed so the initial design can be improved. After the initial part is printed, the solid model will be modified as needed, which may include a different surface pattern or other small alterations. Different surface patterns will be tested based on grip quality while ensuring that the product is still strong enough for its desired application. An FFF additive manufacturing process will be used initially to determine the quality, strength, precision, and functionality that can be attained by a user that may want to complete a project like this on their own. FFF printing is a much cheaper method compared to SLA, making it more accessible to the public.

The maximum stress and its effect on the structural design of the handle will be considered. SolidWorks will be used to determine the maximum stresses under specific loading conditions after each iteration of the design. This will be a major factor in finalizing an optimal structural design. User feedback as to how they handle looks and feels while in use will also be another key factor in determining the final geometry.

Once the design has been finalized, the next iteration will be printed using the Formlabs Rigid resin due to the increased resolution and material strength. This will give insight into how accurate, strong, and fine of a finish can truly be attained for this handle in an additive manufacturing process. This will allow for the comparison of design changes as well as the differences between FFF and SLA additive manufacturing processes. Since each process also utilizes different materials, the strength and surface finish of each polymer will be compared. Ultimately, the main goal is to produce the most appealing, ergonomic, and structurally sound knife handle possible.