Project Overview

The purpose of this project is to design and produce a functional lock and key system from entirely 3D printed components. The team anticipates that most of the components will be straight forward to produce, such as the key and the housing for the pins and springs. However, careful material selection will be required when creating the spring elements as well as the pins. Additional considerations include tolerancing, strength of materials, cost, and the overall practicality of the final product. A successful final design will have a functional lock mechanism which can be opened and closed smoothly. The springs will be sufficiently elastic as to not wear out over time, and the pins should be strong enough to withstand large shear forces in the event that someone tries to break open the lock.

Preliminary Design

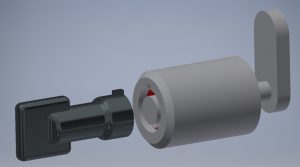

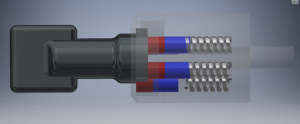

Figures 1.1 and 1.2 below show a preliminary design for the functional lock and key. Key components include the pins, springs, and housing, which will all be printed separately.

Figure 1.1&1.2. Initial conceptual design for lock and key system (top). Internal locking mechanism with pins shown in red and blue and springs in silver (bottom).

The preliminary materials used for the design will be Grey Pro for the body and pins and Elastic 50A for the springs; the preliminary additive manufacturing method to be used will be 3D printing using Formlabs SLA machines.

Manufacturing Considerations and Parameters

The lock pieces are generally quite small, and because of resolution constraints when 3D printing with the available printers, it may be necessary to scale up the design. In addition, several materials will likely need to be used in the assembly of the lock. The strength and durability of the material is important to consider as a lock should be able to secure what it is locked to. The strength of the lock can be optimized via varying the wall thickness and choosing a strong material.

A second consideration is the post processing required before assembling. We will most likely need to use support when printing the casing and will have support on any of the Formlabs parts, which will need to be removed and the parts sanded. When printing the springs, a lot of support will have to be used and the post-processing could potentially prove to be significantly more difficult due to the shape of the springs.

Additionally, since there are so many parts composing the lock, defining appropriate tolerances will be an important manufacturing consideration in this design. It will be important to allow for appropriate space between the components while also ensuring the lock cannot be easily taken apart, making it a poor lock. It will be important to choose a tolerance that is small enough to satisfy this while also choosing a tolerance large enough to print all these parts with a reasonable print time.

An additional consideration is minimizing costs of the prints. The most effective way to do this is by choosing the most affordable resin that still has the strength properties necessary for a lock. Additionally, optimizing wall thickness to be sufficiently strong while also minimizing the amount of material for the print can help to minimize cost. The amount of material can also be further minimized by choosing an appropriate orientation of the part on the printer to minimize the amount of support that will be needed to print the part.

When choosing slicing direction, the function of each component will need to be considered. Certain components, such as the pins and tumblers, will be subjected to primarily shear forces perpendicular to the cylinder axis. Slicing and printing the cylindrical pins and tumblers along the axis is ideal for the printing process because it avoids using support. However, this printing direction aligns the layer boundaries and shear forces from the lock. Additional support may be necessary to reduce the negative impact of the anisotropy from the 3D printing process.

Proposed Analysis

Because a functional lock usually contains many small parts that contribute to its operation as a whole, a good idea for a first print trial would be to analytically determine which parts would be the smallest and print experimental versions of these parts so that we can determine if the resolution of the printers we intend to use will be sufficient. If not, we may consider scaling up the size of the design as mentioned earlier. There will also need to be multiple prints made so that individual parts can be made one at a time and tested to see if they properly fit within previously printed components and function properly. After ensuring the prints are an appropriate scale, the next step in the analysis should include stress testing the springs and the pins to ensure durability. The results of the stress testing will help to finalize dimensions such as radii and wall thicknesses in the final design. Depending on the results of the stress testing, the team will be able to determine the viability of 3D printing a plastic lock in comparison to current metal locks on the market in categories of strength and reliability of the product.