Introduction

Fused Filament Fabrication (FFF) is among the most popular additive manufacturing (AM) technologies available. Materials used in FFF are primarily polymers, low melting temperature metal alloys, and even composite materials. Studies have been performed to determine the mechanical properties of components fabricated by FFF. It has been observed that structural parameters such as filament separation, printing orientation, and material layers have a great influence on the mechanical properties of FFF components. This highlights the importance of understanding the structure-property relation in parts fabricated using this AM-technology. Building on past works, it is of interest to determine the effect of varying part layer height and number on the longitudinal (Xt) and transverse (Yt) tensile strength. Two sample preparation methods will be explored to observe the effect of the layer height and number: 1) fixed sample layer height and 2) fixed sample thickness. By varying the effect of the number of layers at a fixed standard sample height, it is possible to identify the critical layer number, which identifies the point at which the mechanical properties of the proposed part do not change, regardless of the number of layers that are added. By varying the layer height at a fixed standard sample height, it is possible to identify the relationship between deposition pattern orientation and layer height to tensile strength.

Preliminary Design and Maunfacturing Choice

Our printed test piece is a simple rectangular plate (Fig. 1) that will be printed using the FFF process. The Ultimakers in the Makerspace will be the printer of choice for this project.

Figure 1: Model of simple test piece

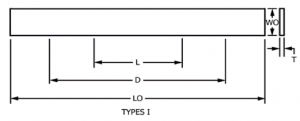

The dimensions of the test piece will be based on the following Type I measurements (Fig. 2).

Figure 2: Dimensions of test piece

Proposed First Print Trial

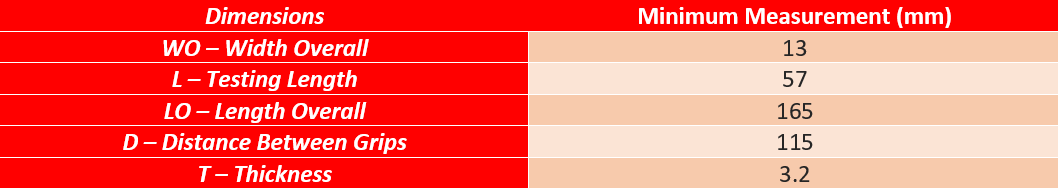

For the proposed project, the samples can be produced without a need for a support and printed in the same run. Cura will be used for producing the stl files necessary for the FFF equipment. Due to the possibility of artificially changing the mechanical properties of the material, the layer heights chosen cannot exceed the nozzle diameter of the FFF printer. To verify the effect of layer number on the tensile strength of the parts, a minimum of 5 samples with the same print orientation, layer number, sample height, and thickness must be printed. The first print trial should focus on optimizing the print of each sample before manufacturing the 5 prints. Common errors associated with part warpage, thermal shrinkage/expansion, and other deviations are expected and must be corrected/minimized on a per sample basis before printing the final samples. The PLA material should not have any additives (such as color additives) and the samples should aim to be produced from the same spool to avoid any deviations due to the material origin. The samples will be printed in two orientations: 0 and 90 (Fig. 3).

Figure 3: Print Orientations

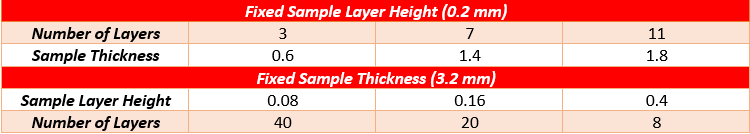

The first set of experiments will have a fixed layer height and a varying number of layers and final heights (Fig. 4). These experiments aim to identify the critical layer number, which identifies the point at which the mechanical properties of the proposed part do not change. The second set of experiments will have a fixed sample thickness and a varying sample layer height (Fig. 4). These experiments aim to identify the effect of the sample layer height on the properties of the part. This can also be used to confirm the effect of the critical layer number.

Figure 4: Layer parameters of each set of test pieces

Emery Cloth will be used to grip the sample for sufficient contact and friction between the machine grips. The samples will be subjected to tensile testing while capturing the stress, strain, and displacement until rupture occurs. ASTM D3039 will be followed when visually identifying the rupture and capturing the engineering tensile strength data. Xt and Yt will be observed throughout experiments at varying number of layers, thicknesses, layer heights, and orientations.