Our Project

Currently our senior design project is to create a hybrid rocket engine that operates on a solid fuel and liquid oxidizer. The solid fuel is a mixture of a Hydroxyl-terminated polybutadiene (HTPB) fuel and Methylene diphenyl diisocyanate (MDI) as the curative. Our senior design team has access to these casted materials and a facility for conducting the process. This fuel is created by pouring the HTPB into a cast and then adding MDI to solidify the mixture.

The goal of this project is to additively manufacture the mold assembly such that we can achieve different complex geometry for the core of the mold. There are several different fuel grain geometries that produce different thrust curves for the rockets as seen in Figure 1. To maintain a constant thrust during our burn, profiles 2 and 3 are of interest for additive manufacturing. Manufacturing patterns such as 2 and 3 are difficult to machine using traditional methods so the use of additive manufacturing can be a cost and time effective alternative.

Figure 1: Fuel grain geometries and thrust profiles [1]

Figure 1: Fuel grain geometries and thrust profiles [1]

Two additive manufacturing methods that the makerspace provides are fused filament fabrication (FFF) and stereolithography (SLA). Since casts are to be manufactured, surface finish of the final part is of paramount interest. Therefore, the part will be manufactured with SLA since the laser used in the process allows for a more accurate dimensioned part and a smoother surface finish. The material used in this will be a castable filament made by Formlabs known as the “rigid” filament that the makerspace has on stock.

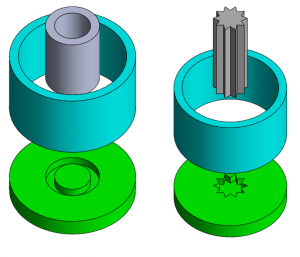

Initially, scaled down samples of these casts will be manufactured to allow us to iteratively adjust our printing material and parameters to ensure an adequate surface finish. Small prototype casts for the circular tube and star patterns can be seen in Figure 2.

Figure 2: Prototype circular tube and star pattern casts

Figure 2: Prototype circular tube and star pattern casts

First Print Trial

To validate our material selection and printing method, the circular tube design will be manufactured first. The resolution and tolerancing of this first print will be analyzed to allow for iterative changes to our printing parameters. Next, this sample cast will have the fuel ingredients casted inside and then the mold will be removed. Depending on the surface finish’s impact on mold removal, the material and or printing parameters may need adjustment. Once these changes are in effect and there is a satisfactory cast produced, the star pattern casts will be manufactured before scaling up the casts completely.

References:

[1] Braeunig, R. A., Basics of Space Flight: Rocket Propulsion Available: http://www.braeunig.us/space/propuls.htm.