ME 514

Team #4

Shengyuan Zhang, Kade Wilson, Saeed Badahdah, Griffin Zacharias

March 1, 2024

ULTRA Comfort Custom Airpods Proposal

Brief Explanation

Our project was inspired by custom fitting hearing aids, which are 3D printed. For our project, we want to make custom fitted sleeves for Apple Airpods. The geometry of the sleeves will be derived from a 3D scan of each group members’ ear using a mold. Once the geometry is defined, the team will explore printing the sleeves with various flexible materials based on feasible technology.

Objective

The objective is to utilize 3D scanner technology at the MakerSpace to create a scan of our moldable wax earplugs. This would allow us to incorporate the airpod inside the scanned sleeve and generate a customized sleeve for customers who suffer from airpods falling out of their ears during simple day to day activities.

Preliminary designs and manufacturing considerations

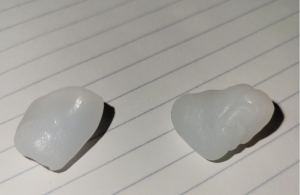

The Airpod might need minimal support in order to print utilizing SLA printers. We anticipate that we can print many customized sleeves in a single print. We realized that our scanned sleeves that host the airpod are going to be in direct contact with the skin, and in order to avoid any skin related health issues, we believe the best option is to utilize a medical or biocompatible polymer grade. After an initial search of potential feedstock, BioMed Clear resin from Formlabs is identified as a potential candidate for our project. Due to the nature of this project, we will not have “Part Drawings” in the traditional sense. Because the part being printed is based on a 3D scan, there is no need for 2D drawings. Instead, the 3D scan will be converted directly into a 3D model. We also anticipate that further post processing might be needed as we learn more from this experience. Figure 1 below shows the wax molds that will be scanned and then printed.

Figure 1: Ear Plug Molds

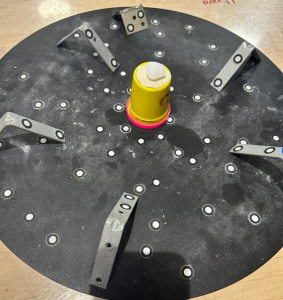

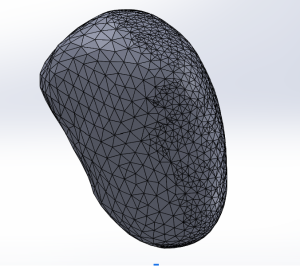

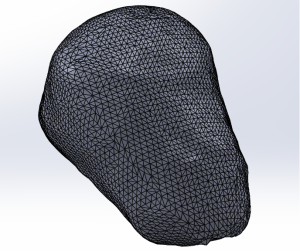

The team is currently working on creating initial scans of the wax plug. To get a better understanding of how the scanning process will be used, a link to a similar project is included: https://www.uniz.com/us_en/blog/post/diy-apple-airpods-to-your-custom-earphone/. We used a Creaform Handyscan 700 to scan the wax molds (figure 2), which were then turned into stl files. Our setup for the 3D scanning process is shown in figure 3. The resulting mesh models are shown in figures 4 and 5 below. Our next step is to refine these models to fit with earbuds before 3D printing them.

Figure 2: Creaform Handyscan 700

Figure 3: 3D scanning setup

Figure 4: Left Earbud Solidworks Model

Figure 5: Right Earbud Solidworks Model

Course of Action

- Research 3D scanning technology available at the makerspace and select the scanning technique that is best suited for this application.

- Learn how to use the selected scanning technology. Connect with Makerspace experts and seek their advice in order to ensure our scans are successful.

- Order moldable wax earplugs to be used as our scannable object. Each team member will mold their own inner ear geometry using a wax earplug.

- Reserve 3D scanners at the Makerspace and scan the molded wax ear plugs.

- Use post processing software (VX Elements) to obtain a 3D model from the scan. Convert the model into an STL that can be 3D printed.

- Research and consider material selection.

- Research and consider additive manufacturing printing process.

- Conduct first print trial.

- Based on the results of the first print trial, do troubleshooting.