Description: Create an adjustable stand for laptops. The proposed design is to make the legs adjustable to change the height of the stand.

Project Overview:

Our project aims to create an adjustable laptop stand using SLA printing technology. The goal of this project is to create an adjustable system that can be used for a wide range of laptop models and laptop rack applications. Our laptop stand will allow independent adjustment of both the front and back legs of the stand, which will allow the user to adjust the overall height of the stand as well as the resting angle of the laptop. The stand will also be designed to handle a range of laptop sizes. This will be done by designing the stand to hold smaller laptops without excess material, but being sturdy enough to support larger laptops despite the smaller size of the stand.

Manufacturing Concerns/Considerations:

There are multiple manufacturing considerations we will examine as we experiment with this project. Firstly, we want to optimize the amount of material used to print the part without compromising the strength of the stand. Along with this, the laptop stand should also be able to easily adjust its height and angle, and be suitable for laptops of various sizes. Another design consideration is finding the correct tolerances for the adjustable aspects of the design and the assembly parts. In terms of the printing considerations, we need to be aware of what kinds of post-processing will be necessary. For SLA, the parts need to be washed and cured after printing. Depending on the surface finish achieved by the print, we may also want to sand down some aspects of the part to make it smoother. The last important consideration is involving the material that we will select for the part. It needs to be able to withstand a laptop’s high temperatures when they release heat. As well, we are considering adding a second material to the bottom of the legs and/or the plate that holds the laptop to prevent it from slipping. This material would need to be flexible/elastic to provide grip.

SLA resin Material Properties:

Resin types available at makerspace: Clear, White, Black, Flexible 80A, Elastic, Durable, Rigid, High Temp

| Properties | Durable Resin | High Temperature Resin | Flexible Resin | Elastic Resin | Clear, Black,Colored Resin |

| Ultimate tensile strength | 31.8 MPa | 58.3 MPa | 7.7-8.5 MPa | 3.23 MPa | 65 MPa |

| Elongation at failure | 49% | 3.3% | 75-85% | 160% | 6% |

| Heat deflection temp. @ 0.45 MPa | 43.4 C | 142 C | – | – | 73 C |

| Tear strength | – | – | 13.3-14.1 kN/m | 19.1 kN/m | – |

| Flexural modulus | 0.82 GPa | 2.62 GPa | – | – | 2.2 GPa |

Table 1: The table above provides material properties in metric units for Clear Resin, Black Resin and Color Kit, Elastic Resin, Flexible Resin, High Temperature Resin, and Durable Resin post curing according to formlabs.

As the goal of this project is to be able to create a functioning laptop stand with adjustable height and angle, we are looking for a material that can withstand not only the weight of the laptop, but also the heat the battery expels and also not slip off the stand. The ultimate tensile strength is important but because the stand will be in compressive loading, the flexural modulus is more useful. The flexural modulus computes the ratio of stress to strain in the materials ability to resist bending. By looking at this, the high temperature resin has the largest value, indicating it has the greatest resistance to bending and is more rigid. With the highest flexural modulus and resistance to temperature, the high temperature resin is most applicable for our project. We might also utilize the flexible resin for slipping purposes on the surface of the laptop platform. The flexible resin is more favorable over the elastic resin as it has a significantly better ultimate tensile strength and elongation at failure with a comparable tear strength. While price is a factor, the difference in resin price is 5 cents per milliliter for the flexible, elastic, and high temperature resins as compared to the standard clear resin. Also the durable resin is 2 cents more per milliliter than the clear resin. Since the types of resin available are dependent on the MakerSpace Labs, we have compared their materials with FormLabs material properties.

Preliminary Designs:

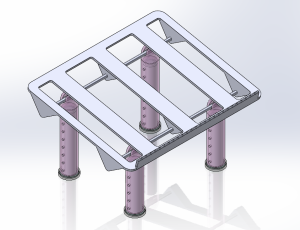

Figure 1. Isometric View of the first iteration of the laptop stand assembly

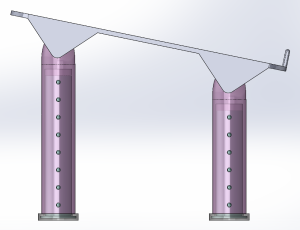

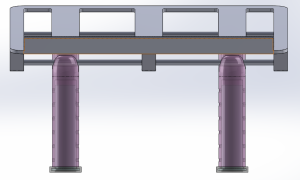

Figure 2 – 3. Side View and Front View of the first iteration of the laptop stand assembly

Proposed Printing Process:

Multiple prints will be required to create the adjustable laptop stand due to its size and the limited room in the SLA printers in the Makerspace. The first printing iterations will be used to test the dimensioning of the printing process as well as the surface finish of the printed parts. The preliminary prints will also be used to test different variations of position locking designs, so that multiple options can be prototyped for functionality. The iterative printing process will allow us to test and hone various design options for each of our possible component combinations to achieve the best possible design for our final print. After testing all options our team will perform a final print using the best design options or existing parts from previous iterations to complete our final physical prototype.