SolidWorks Simulations

An important design consideration of a 3D printed lock in comparison to a traditional metal lock is its durability and ability to withstand substantial force without breaking. Due to COVID-19 and limited in-person opportunities to conduct testing, SolidWorks simulations were conducted to better understand how metal versus plastic compares under various conditions. The first simulation was a drop test with a drop height of 10 [ft]. The simulation was done for both an ABS plastic lock and a brass lock, and the results are shown in Figure 1 and Figure 2 below.

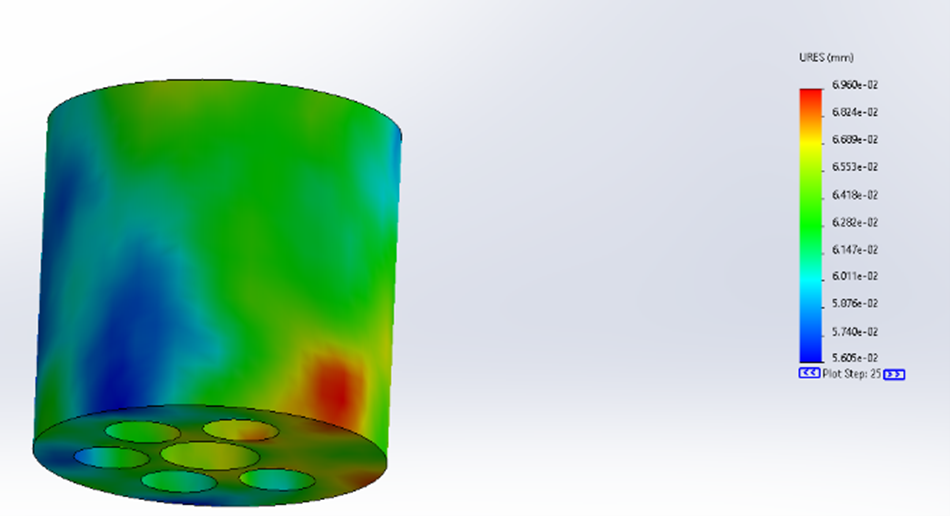

Figure 1. Brass lock drop test results.

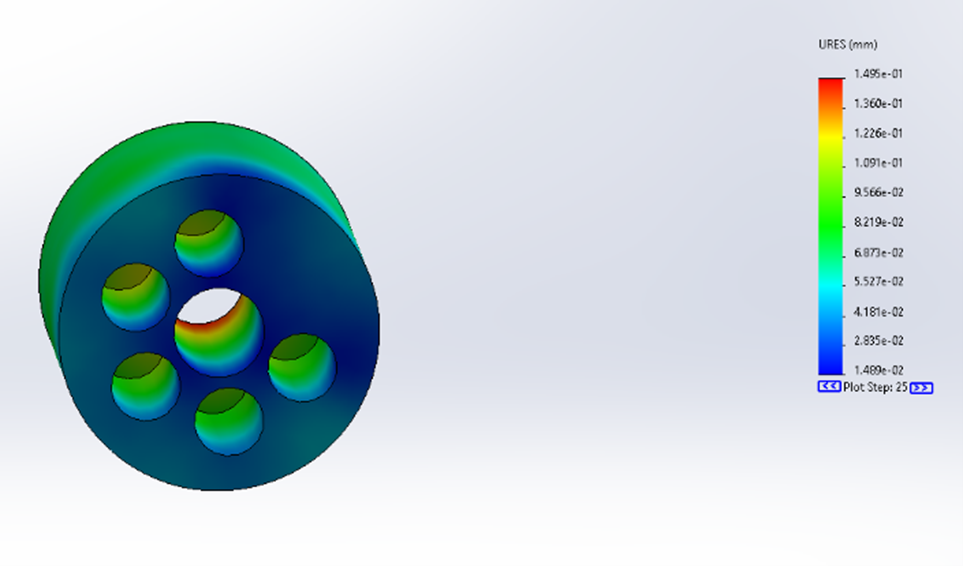

Figure 2. ABS plastic lock drop test results.

A key takeaway from the drop test results is that the ABS plastic lock had a larger maximum displacement than the brass lock, for total maximum displacements of 0.1498 [mm] and 0.006960 [mm] respectively. Additionally, the largest deformations on the brass lock were in less critical areas of component since damage on the outer part of the body would not affect the ability to insert pins into the component.

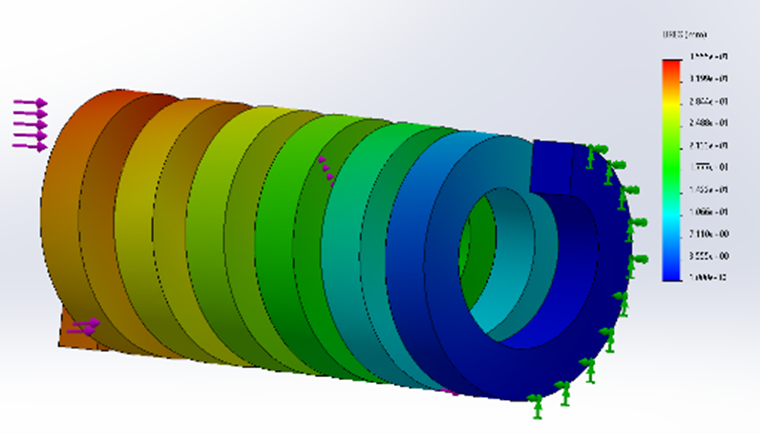

It was also important to gain an understanding of the viability of using 3D printed springs in the design. To do this, a SolidWorks simulation was done for a compression test of 5 [lbs] on the spring with a fixed end for both ABS plastic and Carbon Steel was completed. The results of the of the simulation are shown below in Figure 3 and Figure 4.

Figure 3. ABS plastic spring compression test results

Figure 4. Carbon steel spring compression test results.

As shown in the figures, the maximum displacement of the ABS spring compared to the Carbon Steel spring is significant, with maximum values of 35.5 [mm] and 0.3383 [mm] respectively. These simulation results match expectations, since the 3D printed spring has very little strength compared to the metal spring that was purchased. With much less force than 5 [lbs], the 3D printed spring compressed easily making it not a viable option for use in the overall lock design. Therefore, a metal spring was purchased from McMaster Carr in order to allow for a fully assembled final prototype.

Results and Discussion

With the implementation of metal springs, the rest of the 3D printed lock and key components were able to be assembled into a functional prototype. Figure 5 shows all the individual components before assembly, including the metal springs.

Figure 5. Final set of 3D printed components and steel springs.

After manual sanding to reduce friction between the pins and lock body, the parts were assembled into a fully functioning lock mechanism as shown in Figure 6. When the key was inserted, the interface between the pins aligned with the shear plane between the Cylinder and Lock Body, allowing the key to rotate the cylinder and latch to the unlocked position.

Figure 6. Final assembly of functioning 3D printed lock mechanism.

If another round of printing and assembly were planned, a couple adjustments could be made to improve the function of the lock. First, a mechanical joining method between the lock cap and lock body, would be significantly more functional than the adhesive used for the final print.

In addition, placing the interface between the two components further towards the rear of the assembly would make it more difficult to separate the two components, improving the mechanisms function as a lock. Finally, the springs that were used were appropriately sized, however the combined compression force of the 5 springs made actuating the mechanism difficult and would result in increased wear on the pins and Cylinder over time.

Conclusion

The final prototype shows that all components of a functional lock and key system can be 3D printed except for the springs. Currently, there is a lot of ongoing research in the viability of 3D printed springs that could soon allow for the entire assembly to be created with additive manufacturing processes. The major factor that did not allow for 3D printed spring in the design was the lack of strength in the material options available.

Additionally, this project highlighted the additional tolerancing needed when 3D printing components on such a small scale as compared to using a smoother finish material such as metal. It took a great deal of post-processing to get all the components able to assemble, which is an important factor to consider if this design were to be produced in large quantities in the future. Even with the high precision of SLA technology in the Formlabs printers, tolerance between mating parts had to increase significantly from the original print.

Moreover, the fully functioning lock assembly was less versatile and durable than a standard metal lock. Although compression tests in SolidWorks proved that the springs themselves could handle a significant amount of force, the force needed to compress the springs will eventually cause significant wear and tear on neighboring critical components of the assembly. Therefore, the most critical future work for the lock and key system would be optimizing the spring design to allow for both strong springs that will not decrease the longevity of the overall assembly.

Anna Flemma, Joshua Kurkiewicz, Zach Miller, Antonio Rubio, and Josh Schroeder