Project Overview

A combination of fused filament fabrication (FFF) and laser cutting techniques will be used to create a travel-sized chess set. This design will be created entirely from scratch, incorporating known concepts and popular methods, such as hidden magnetic pieces, along with novel concepts, such as transformable pawns. This project aims to create a travel-sized chess set that closely mimics the experience of using a fully sized wooden chess set while incorporating additional benefits relating to portability and convenience. This is all achievable with the 3D printing resources available in the UW-Madison Makerspace and Polymer Engineering Center.

Preliminary Design

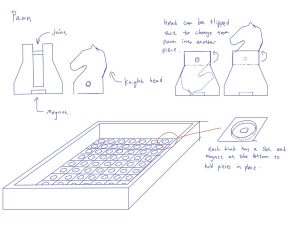

Figure 1: Preliminary design sketches for the magnetic chess board and its transforming pieces

Design and Manufacturing

This travel chess board necessitates several constraints to ensure its functionality. Dimensional constraints are largely dependent on the height of the pieces, as the pawns will incorporate a mechanism to expand into other full-scale counterparts. The correct piece height must be chosen to ensure they are easy to handle while fitting in a travel-sized box. The height of the pieces also affects the size and clearance required within the box. Regarding material selection, the chosen material must be strong enough to withstand the force associated with the transforming mechanism within the pawns, as outlined in the initial material selection process. The limitations of the additive manufacturing process will guide the pawn design along with its assembly. Features with significant overhangs such as the bar in the pawn mechanism or the recess for the magnets will likely need to be printed in multiple parts to ensure the final tolerances and overall print quality of the parts are sufficient.

Initial Methods and Materials

FFF printing with PLA thermoplastic material will be used for the first attempt/prototype due to the higher material strength/rigidity as compared to other printing methods and materials. This method of printing will be used for the pieces and the box to house the board. Laser cutting will be used to cut the chess board to shape, and later post-processing will be done to color the tiles on this board appropriately.

The material strength of PLA is most likely sufficient for the internal mechanism of the chess pieces, and this will be tested in the experimental trials. Additionally, PLA is known to be the most readily available and cheapest material to 3D print with. For laser cutting, softwood will be used first as this type of wood is easiest to cut as well as paint.

Trials and Experimentation

Several key principles need to be tested before printing the final assembly. The first and most critical concept is to validate the size of the pieces along with the pawn’s mechanism used to transform them into their respective larger pieces. Experimentation also must be done on the degree of portability of the design. This will include trying to fit the product in several different common bags and commenting on its degree of comfort. The magnet’s strength is another concept that requires validation, as the magnets must be strong enough for the board to hold the chess pieces in place at any orientation, but light enough for the user(s) to move, remove, and place the chess pieces into their respective positions while interacting with them.

Possible issues associated with this concept include choosing the appropriate tolerances for the FFF 3D printer being used. The strength of the bar that acts as the swivel point for the transformable pieces must also be tested to ensure it will withstand the stresses of normal use. Similarly, the press fit of the box itself needs to be tested along with that of the magnets. Both of these are going to be of different size recesses and dialing in the tolerancing for press fit will be essential to the product for both the aesthetics as well as eliminating the need for any other fastening methods. Ultimately, the tolerance and the accuracy of the 3D printer need to be explored and calibrated to allow for a successful final product.